danieltanner

DIY

- Reaction score

- 0

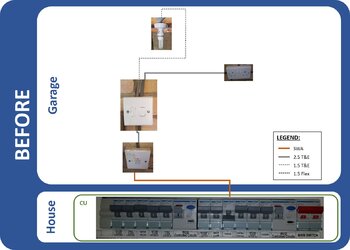

My Current Setup (see image BEFORE.jpg):

The wiring for my existing detached garage is shown (see image BEFORE.jpg). The house consumer unit provides RCD and MCB (Hager MTN116 B16 – 16A) protection and is wired to the garage via SWA. The SWA armour is earthed where it leaves the house. It enters the garage via the back of a 20AX Switch to isolate the garage and leaves out the top of this as 2.5 T&E. From here it runs to a fused spur, which provides a 3A fused 1.5 T&E cable for the single lamp and a 2.5 T&E cable for one double socket.

The light is looped in at the switch, so there is a single run of 1.5 T&E across the garage to the holder that terminates there. Similarly for the double socket there is a single run of 2.5 T&E to the socket that terminates there.

What I need:

I am based in the UK and enjoying doing woodwork and want to improve the garage to support this hobby. The single bulb does not provide anywhere near enough light and one double socket does not provide enough outlets for my needs and not enough flexibility about where I am working in the garage. I don’t have any equipment that places much load on the electrics but if I run a vacuum extractor (Henry) at the same time as my circular saw I cannot turn on the radio. Also having sockets on both sides of the garage would provide me more flexibility around where I can work on specific tasks. Additionally, as my woodworking raises lots of dust I am also keen for good IP rating and will add a glanded setup with 20mm PVC conduit where I can.

What I am planning to do (see image AFTER.jpg):

1) Existing fittings – upgrade existing fittings (see image AFTER.jpg): move to MK Metalclad fittings (earthing the boxes and faceplates as I go) and adding 20mm conduit and glands. The current fittings have a significant amount of wood dust in them already as the plastic pattresses have no knockouts so lumps have been hand sawn out to let the cables pass, which has left large holes at the tops/bottoms of all fittings.

2) Lights – remove current light fixture and add four LED strip lights (see image AFTER.jpg): remove the existing light fixture and replace it with a junction box (say Wago XL). Then wire each of the four new LED light strips (Philips Ledinaire WT065C LED68S/840 PSU L1500) to this junction box using 1.5 flex (as the new fittings have glands/grommets for round cable only). I will use three 5-pole 221 series Wago connectors to wire all of the lives together, then all of the neutrals together and then earths together (so the live core from the switch and a live core from each of the four new fixtures will be spliced together by a 221 connector, and same for neutral and earth). I could wire/loop in and out of each of the new fixtures but I think it would be neater and may require less wire to run to a junction box that is centred between the four (as the wire from the switch across the garage already terminates here).

3) Sockets – add three new sockets (see image AFTER.jpg): My plan for the sockets is add a new double socket next to the existing one (knock out the side of the existing wall mounted pattress, pair in a short run of 2.5 T&E from it to the new socket next to it). Additionally, I would add a junction box into the existing 2.5 T&E cable that feeds these two sockets to branch off a new run of 2.5 T&E across the rafters and down the other side of the garage to create a matching pair of double sockets on the other side of the garage. All of the wiring is achieved by pairing cores (i.e., lives with lives, etc.).

QUESTIONS – I have numbered these in the hope it will make them easier to respond to:

1) Does this sound like a sensible approach for the sockets and lights?

2) The current isolator switch (where the SWA enters the garage) is 20AX rated, is it reasonable practice to replace this with a 20A rated switch instead as I am using LED and not fluorescent lights (as I found a nice 20A version at a good price)?

3) I expect that the lights will nominally consume around 1A (55W x 4/240 = 1Aish) but inrush is high (6.9A each over 50ms). I will use a standard 3A fuse on the fused spur for this lighting circuit, is this reasonable?

4) Do you have any recommendations for a junction box that may have better IP rating than the Wago XL I mentioned for the lights (ideally catering for four flex inputs and one 20mm conduit gland)?

5) Do you have a good recommendation for a 20mm gland compatible junction box for the sockets? Could I simply use three 3-pole 221 series Wago connectors in a 3 Way 20mm Tee Box for this – i.e., splice them in a conduit box?

6) A cursory run through the regs of Part P suggest that I am good to undertake this work myself (without notification or test result submission) as both are extensions to existing circuits (i.e., “additions and alterations to existing installations outside special locations”). Am I correct in this? I will also consider how this is “tested and certified in accordance with BS7671” before being connected.

The wiring for my existing detached garage is shown (see image BEFORE.jpg). The house consumer unit provides RCD and MCB (Hager MTN116 B16 – 16A) protection and is wired to the garage via SWA. The SWA armour is earthed where it leaves the house. It enters the garage via the back of a 20AX Switch to isolate the garage and leaves out the top of this as 2.5 T&E. From here it runs to a fused spur, which provides a 3A fused 1.5 T&E cable for the single lamp and a 2.5 T&E cable for one double socket.

The light is looped in at the switch, so there is a single run of 1.5 T&E across the garage to the holder that terminates there. Similarly for the double socket there is a single run of 2.5 T&E to the socket that terminates there.

What I need:

I am based in the UK and enjoying doing woodwork and want to improve the garage to support this hobby. The single bulb does not provide anywhere near enough light and one double socket does not provide enough outlets for my needs and not enough flexibility about where I am working in the garage. I don’t have any equipment that places much load on the electrics but if I run a vacuum extractor (Henry) at the same time as my circular saw I cannot turn on the radio. Also having sockets on both sides of the garage would provide me more flexibility around where I can work on specific tasks. Additionally, as my woodworking raises lots of dust I am also keen for good IP rating and will add a glanded setup with 20mm PVC conduit where I can.

What I am planning to do (see image AFTER.jpg):

1) Existing fittings – upgrade existing fittings (see image AFTER.jpg): move to MK Metalclad fittings (earthing the boxes and faceplates as I go) and adding 20mm conduit and glands. The current fittings have a significant amount of wood dust in them already as the plastic pattresses have no knockouts so lumps have been hand sawn out to let the cables pass, which has left large holes at the tops/bottoms of all fittings.

2) Lights – remove current light fixture and add four LED strip lights (see image AFTER.jpg): remove the existing light fixture and replace it with a junction box (say Wago XL). Then wire each of the four new LED light strips (Philips Ledinaire WT065C LED68S/840 PSU L1500) to this junction box using 1.5 flex (as the new fittings have glands/grommets for round cable only). I will use three 5-pole 221 series Wago connectors to wire all of the lives together, then all of the neutrals together and then earths together (so the live core from the switch and a live core from each of the four new fixtures will be spliced together by a 221 connector, and same for neutral and earth). I could wire/loop in and out of each of the new fixtures but I think it would be neater and may require less wire to run to a junction box that is centred between the four (as the wire from the switch across the garage already terminates here).

3) Sockets – add three new sockets (see image AFTER.jpg): My plan for the sockets is add a new double socket next to the existing one (knock out the side of the existing wall mounted pattress, pair in a short run of 2.5 T&E from it to the new socket next to it). Additionally, I would add a junction box into the existing 2.5 T&E cable that feeds these two sockets to branch off a new run of 2.5 T&E across the rafters and down the other side of the garage to create a matching pair of double sockets on the other side of the garage. All of the wiring is achieved by pairing cores (i.e., lives with lives, etc.).

QUESTIONS – I have numbered these in the hope it will make them easier to respond to:

1) Does this sound like a sensible approach for the sockets and lights?

2) The current isolator switch (where the SWA enters the garage) is 20AX rated, is it reasonable practice to replace this with a 20A rated switch instead as I am using LED and not fluorescent lights (as I found a nice 20A version at a good price)?

3) I expect that the lights will nominally consume around 1A (55W x 4/240 = 1Aish) but inrush is high (6.9A each over 50ms). I will use a standard 3A fuse on the fused spur for this lighting circuit, is this reasonable?

4) Do you have any recommendations for a junction box that may have better IP rating than the Wago XL I mentioned for the lights (ideally catering for four flex inputs and one 20mm conduit gland)?

5) Do you have a good recommendation for a 20mm gland compatible junction box for the sockets? Could I simply use three 3-pole 221 series Wago connectors in a 3 Way 20mm Tee Box for this – i.e., splice them in a conduit box?

6) A cursory run through the regs of Part P suggest that I am good to undertake this work myself (without notification or test result submission) as both are extensions to existing circuits (i.e., “additions and alterations to existing installations outside special locations”). Am I correct in this? I will also consider how this is “tested and certified in accordance with BS7671” before being connected.