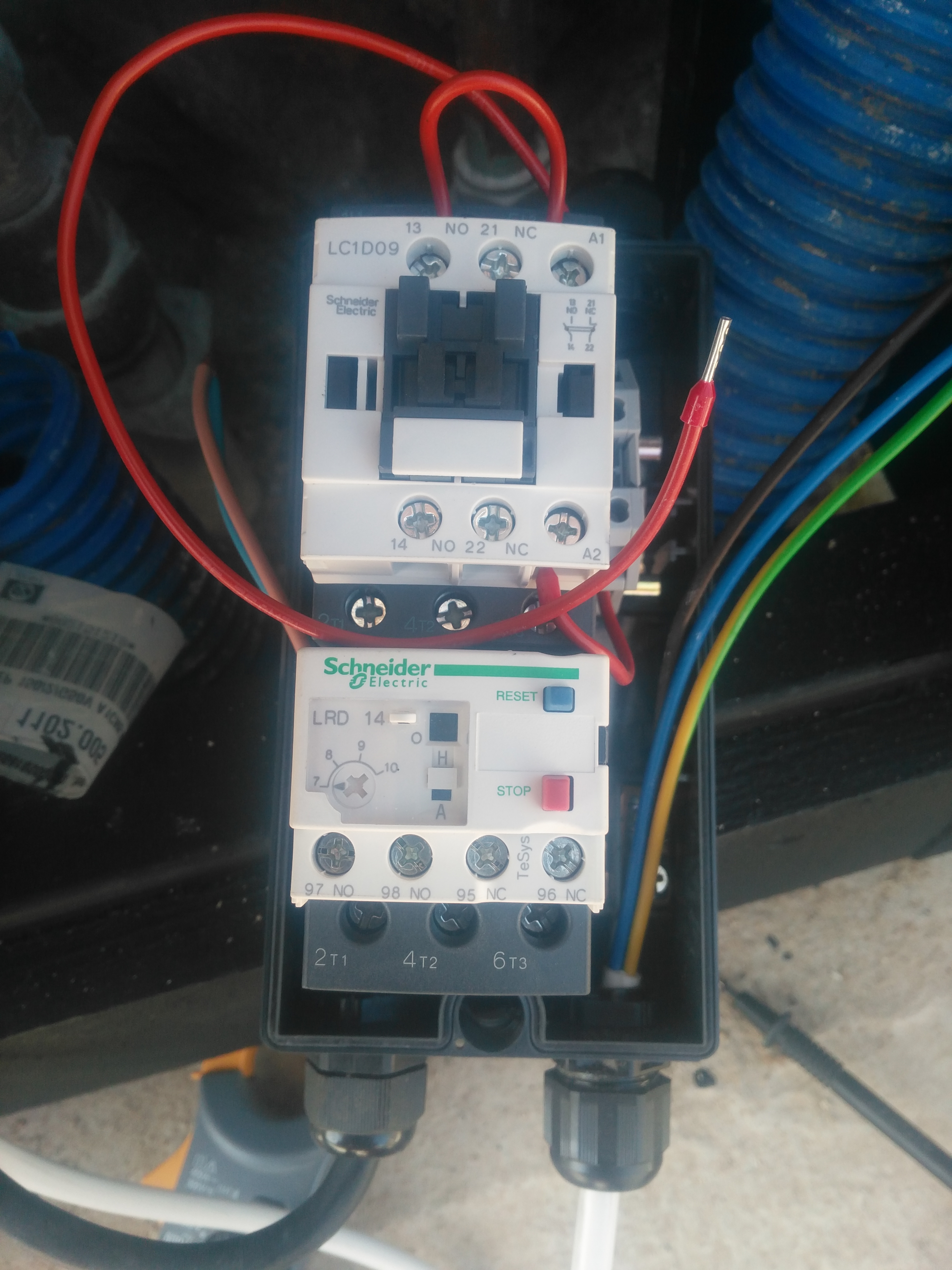

Hi all, never had to wire a domestic sewerage pump before so not my usual line of work. Was told I need a thermal overload for the pump (1.1kw) and this came with a contactor (not sure why it needs a contactor, but it appears that the overload unit need one to plug into. Can anyone please advise on how to wire this? The enclosure has an earth and Neutral link inside.

-

Pro's OnlyElectricians Arms Electrician Talk How to Access The Arms Domestic Electrician Industrial Electricians Wiring, Theories, Regulations Engineering Chat Periodic Testing Problems Electricians Downloads Commercial Electricians Security (Access-Only) Access Private Area Business Related Advice Certification Schemes Electrical & PAT Testing

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter Colin33

- Start date

The contactor needs a control circuit do you have this in place.

D

davesparks

Yes the pump has it's own pre-wired control float. There is also a separate float to indicate high level, which I've wired into an alarm unit..

Ok, and what exactly is it that you have there, is it a DOL starter or just the contractor and overload?

D

davesparks

It's a LE1D09 Schneider enclosed starter..

You should have the schematic for it included in the instructions then.

Just don't forget to adapt it for single phase operation

L

LankyWill

I'm surprised the contractor isn't pre wired into the control panel with the float switches. That said the schematic included should state how to configure the contractor within the circuit. Just make sure the overload is set correctly or could have to fish a burnt motor out of a load of s***.

D

davesparks

I can't make any sense of the schematic, or which one of the ones shown to use. Hence my request for help here

Then perhaps it's time to employ someone who knows what they are doing.

Couldn't find anyone close by willing/able to do it. I wired it up temporarily so that it could be used and decided to ask for help here. If you don't wish to help Dave then why even reply?Then perhaps it's time to employ someone who knows what they are doing.

Can you show the cover for the contactor.

D

davesparks

From what the op has said I think the float switch is already connected directly to the pump and doesn't need including in the control circuit of the starter.

D

davesparks

Couldn't find anyone close by willing/able to do it. I wired it up temporarily so that it could be used and decided to ask for help here. If you don't wish to help Dave then why even reply?

I do wish to help, but if you already have the wiring diagram but can't read it then there's nothing I can do except recommend getting an electrician to do it.

Ah yes you are probably correct so they are just suggesting the thermal overload and not a contactor.From what the op has said I think the float switch is already connected directly to the pump and doesn't need including in the control circuit of the starter.

D

davesparks

Ah yes you are probably correct so they are just suggesting the thermal overload and not a contactor.

Yes, I think a motor protection circuit breaker would have been more suitable than a whole DOL starter.

I am with you on that just wire in and out, easy.Yes, I think a motor protection circuit breaker would have been more suitable than a whole DOL starter.

If you knew how to do it then why not just tell me which connections (they're all marked on the unit in the pic) to put the L/N feed into and which connections to put the L/N pump wires into and which (if any) to link together. Thought that's a pretty straight forward request for someone who is familiar with these?I do wish to help, but if you already have the wiring diagram but can't read it then there's nothing I can do except recommend getting an electrician to do it.

You are asking for advice here not sure this is the way to achieve that.If you knew how to do it then why not just tell me which connections (they're all marked on the unit in the pic) to put the L/N feed into and which connections to put the L/N pump wires into and which (if any) to link together. Thought that's a pretty straight forward request for someone who is familiar with these?

Yes I agree, the client had a company come and install the pump but they didn't do the electrics. I asked what's needed to control the pump and they supplied me the gear as in photo. Seems over the top to me, but that's what I have. I see no reason for the contactor, but assumed it's needed just to house the overload because the overload is not din mountable....No need for that Dave is quite rightly thinking you may have the wrong device for the job.

D

davesparks

If you knew how to do it then why not just tell me which connections (they're all marked on the unit in the pic) to put the L/N feed into and which connections to put the L/N pump wires into and which (if any) to link together. Thought that's a pretty straight forward request for someone who is familiar with these?

To start with I think you have the wrong device for the job.

What you have there can be made to do the job but it seems like an over the top solution.

I can tell you exactly where to put the connections, though a simple diagram has already been posted by someone else.

L and N in to the top of the contactor, L and N out from the bottom of the overload.

The start button needs to be in parallel with the hold in contact

The stop button (if present) and overload terminals 95 and 96 need to be in series with each other and in series with the hold in contact.

You need to loop one of the outgoing connections through the third pole of the contractor and overload to avoid unbalancing the load through it.

I don't know the flc of the motor so cannot tell you where to set the overload trip, you'll have to do that for yourself after reading the data plate.

The overload itself will not disconnect the power in the event of an overload, it purely detects, this is why you need the contactor, the normally closed auxiliary contact on the overload will open and de-energise the contactor in the event of an overload.

If this is to be used just to provide a feed to the pump with a prewired float sw, wire it as my diagram above but ignore the float switch, take the live straight to the overload (terminal 95)

If this is to be used just to provide a feed to the pump with a prewired float sw, wire it as my diagram above but ignore the float switch, take the live straight to the overload (terminal 95)

D

davesparks

Yes I agree, the client had a company come and install the pump but they didn't do the electrics. I asked what's needed to control the pump and they supplied me the gear as in photo. Seems over the top to me, but that's what I have. I see no reason for the contactor, but assumed it's needed just to house the overload because the overload is not din mountable....

It's not just the mounting of the overload that requires the contactor.

An overload trip is just a sensing element, it sends a signal via the contacts 95 and 96 to another device (in your case the contactor) which actually breaks the flow of current to the motor.

Sorry Westward but all too often on these forums people get put down or belittled for asking for help. I don't wish or need to be told to 'get an electrician' I just want some help from someone who is able to do so and if they can't help, why waste their time getting involved?You are asking for advice here not sure this is the way to achieve that.

Thank's guys, becoming clearer now  So live feed to T1 at top of contactor, Live to pump to 2T1 of overload. Neutral in to T2 of contactor, Neutral to pump from 4T2 on overload. Red flying lead shown in photo to 95NC on overload. And link T3 of contactor to 6T3 of overload?

So live feed to T1 at top of contactor, Live to pump to 2T1 of overload. Neutral in to T2 of contactor, Neutral to pump from 4T2 on overload. Red flying lead shown in photo to 95NC on overload. And link T3 of contactor to 6T3 of overload?

So live feed to T1 at top of contactor, Live to pump to 2T1 of overload. Neutral in to T2 of contactor, Neutral to pump from 4T2 on overload. Red flying lead shown in photo to 95NC on overload. And link T3 of contactor to 6T3 of overload?

So live feed to T1 at top of contactor, Live to pump to 2T1 of overload. Neutral in to T2 of contactor, Neutral to pump from 4T2 on overload. Red flying lead shown in photo to 95NC on overload. And link T3 of contactor to 6T3 of overload?

D

davesparks

Thank's guys, becoming clearer nowSo live feed to T1 at top of contactor, Live to pump to 2T1 of overload. Neutral in to T2 of contactor, Neutral to pump from 4T2 on overload. Red flying lead shown in photo to 95NC on overload. And link T3 of contactor to 6T3 of overload?

Nope you've missed out the start and hold in contacts, along with looping through the third set of contacts on the overload to give it a balanced load.

D

davesparks

Sorry Westward but all too often on these forums people get put down or belittled for asking for help. I don't wish or need to be told to 'get an electrician' I just want some help from someone who is able to do so and if they can't help, why waste their time getting involved?

The reason I said get an electrician is that every electrician will have learned this basic DOL starter circuit whilst at technical college doing the theory side of their apprenticeship. Therefore any electrician will know the circuit and be able to connect it up.

Surely it is not a good idea to have the contactor permanently energised.

Should not be a problem, many sites (hospitals for example) have essential sides of switchboards powered via contactors that are permanently energised until power failure then the essential side is fed via a generator.Surely it is not a good idea to have the contactor permanently energised.

A better alternative for this pump application would be to select a manual motor stater (Such as Schneider GV2-ME) which will provide thermal magnetic protection but without the need for any control wiring.

Thermal-Magnetic motor circuit breakers - TeSys GV2 | Schneider Electric - http://www.schneider-electric.com/en/product-range/684-tesys-gv2/

Yes, I'm sure this was briefly covered during my college days but having never had to wire one in over 20 years it's not something I'm familiar with. I certainly don't recall being taught how to couple a thermal overload with one. Well done Dave if you can remember everything you learnt, I'm afraid I'm not that goodThe reason I said get an electrician is that every electrician will have learned this basic DOL starter circuit whilst at technical college doing the theory side of their apprenticeship. Therefore any electrician will know the circuit and be able to connect it up.

Rocboni

-

I wouldn't wire it with a start button surely it's bad design that after a power failure you have to go out and start your sewage pump, could get a bit messy if someone forgets?

This must be a basic system or it would have come with a purpose built panel. The blue button on the front is a reset button to reset the overload if it trips,

This must be a basic system or it would have come with a purpose built panel. The blue button on the front is a reset button to reset the overload if it trips,

Last edited:

O

Ollie Barwick

OFFICIAL SPONSORS

These Official Forum Sponsors May Provide Discounts to Regular Forum Members - If you would like to sponsor us then CLICK HERE and post a thread with who you are, and we'll send you some stats etc

Advert

Thread Information

- Title

- Contactor/overload wiring help pls...

- Prefix

- N/A

- Forum

- UK Electrical Forum

- Replies

- 47

- Unsolved

- --

Thread Tags

Advert

Advert

TrueNAS JBOD Storage Server

-

-

-

Understanding TrueNAS JBOD Servers: A Comprehensive Guide

- Started by Dan

- Replies: 8