I'm insulating, and replacing the wiring, in one of my own (metal, agricultural-type) workshops - fitting 13A/16A sockets on each of the horizontal 'top hat' wall rails, 20m long, with each 4m bay having 4-5 sockets.

This will be done in stages over the next year: the insulation and plasterboard takes a long time, and I'll completely finish/paint each bay before moving on to the next, so as to have an always-working installation.

The sockets on each wall will be wired as RFCs in 2.5mm T&E inside the top hat rail, closed with Celotex and plasterboard. It provides an excellent ready-made concealed trunking system.

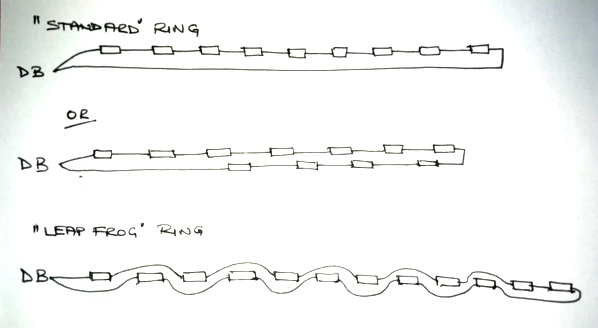

I'd normally wire a ring socket-to-next-socket and so on, then have one often longer run back to the board from the end.

But this time, to make it easy to stop and start work yet still have a functioning ring (by adding a single short link at the end), I'll 'leapfrog' the ring wiring to every second socket.

I have no idea if this is normal practice! Thinking about it, it does feel better-designed anyway, as nearly every socket-to-socket cable run will be exactly the same length.

Have I missed anything?

[automerge]1591826810[/automerge]

Too many words! This is what I mean:

Obviously this question only applies to an 'industrial' application where there are loads of sockets in one long, obvious, visible length.

This will be done in stages over the next year: the insulation and plasterboard takes a long time, and I'll completely finish/paint each bay before moving on to the next, so as to have an always-working installation.

The sockets on each wall will be wired as RFCs in 2.5mm T&E inside the top hat rail, closed with Celotex and plasterboard. It provides an excellent ready-made concealed trunking system.

I'd normally wire a ring socket-to-next-socket and so on, then have one often longer run back to the board from the end.

But this time, to make it easy to stop and start work yet still have a functioning ring (by adding a single short link at the end), I'll 'leapfrog' the ring wiring to every second socket.

I have no idea if this is normal practice! Thinking about it, it does feel better-designed anyway, as nearly every socket-to-socket cable run will be exactly the same length.

Have I missed anything?

[automerge]1591826810[/automerge]

Too many words! This is what I mean:

Obviously this question only applies to an 'industrial' application where there are loads of sockets in one long, obvious, visible length.

Last edited: