Been working at a cinema refurbishment but our firm are not doing the data cables or the speakers. It got to the end of the day and the people who are doing that side of things were pulling what looked like t+e through the studwork on the back wall of one of the screens. The roll was not on a reel, was just lying flat on the floor and as you can imagine there was a twist every foot of the run (which goes along the back wall then down the left and right walls to the speakers). Even though it is just speaker wire could it still create a build up of heat from the eddy currents? I thought I saw in the OSG a regulation about using a cable reel to avoid twists when pulling cables but have looked through it and found nothing. Looked through a few parts of the regs book too and couldn't find anything there either. I expect the builders will start to board over it tomorrow so thought I'd post a query up on here as I know this can be a very informative forum. Cheers guys

-

Pro's OnlyElectricians Arms Electrician Talk How to Access The Arms Domestic Electrician Industrial Electricians Wiring, Theories, Regulations Engineering Chat Periodic Testing Problems Electricians Downloads Commercial Electricians Security (Access-Only) Access Private Area Business Related Advice Certification Schemes Electrical & PAT Testing

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter Paisley

- Start date

Still a mystery to me how many younger Electrician and Installers can't run a length of twin and cpc without a cable roller without getting any twists, still I suppose that's the penalty you have to pay when training and only using a couple of feet of cable.Been working at a cinema refurbishment but our firm are not doing the data cables or the speakers. It got to the end of the day and the people who are doing that side of things were pulling what looked like t+e through the studwork on the back wall of one of the screens. The roll was not on a reel, was just lying flat on the floor and as you can imagine there was a twist every foot of the run (which goes along the back wall then down the left and right walls to the speakers). Even though it is just speaker wire could it still create a build up of heat from the eddy currents? I thought I saw in the OSG a regulation about using a cable reel to avoid twists when pulling cables but have looked through it and found nothing. Looked through a few parts of the regs book too and couldn't find anything there either. I expect the builders will start to board over it tomorrow so thought I'd post a query up on here as I know this can be a very informative forum. Cheers guys

I agree Murdoch, I believe the old ways should be talked about when you do your training, as you must know some times cable reels can be a pain, with cable coming off when pulling cable runs in from a distance.A cable real is cheap, and there's no excuse not to use one

Broom handle, two chairs and a doorway.

Davisonp

-

A lot of professional speaker cable is twisted pair so the cables are twisted together for the full length of the run. More worrying is running T&E for speakers. I was involved on a reverb in a church that had T&E for speaker wire, and once the power was shut off identifying what was power and what was speaker was a nightmare.

O

Octopus

Broom handle & a 5 step ladder ..

corrected that for you!

A few pallets and a off cut of tube does the job as well.corrected that for you!

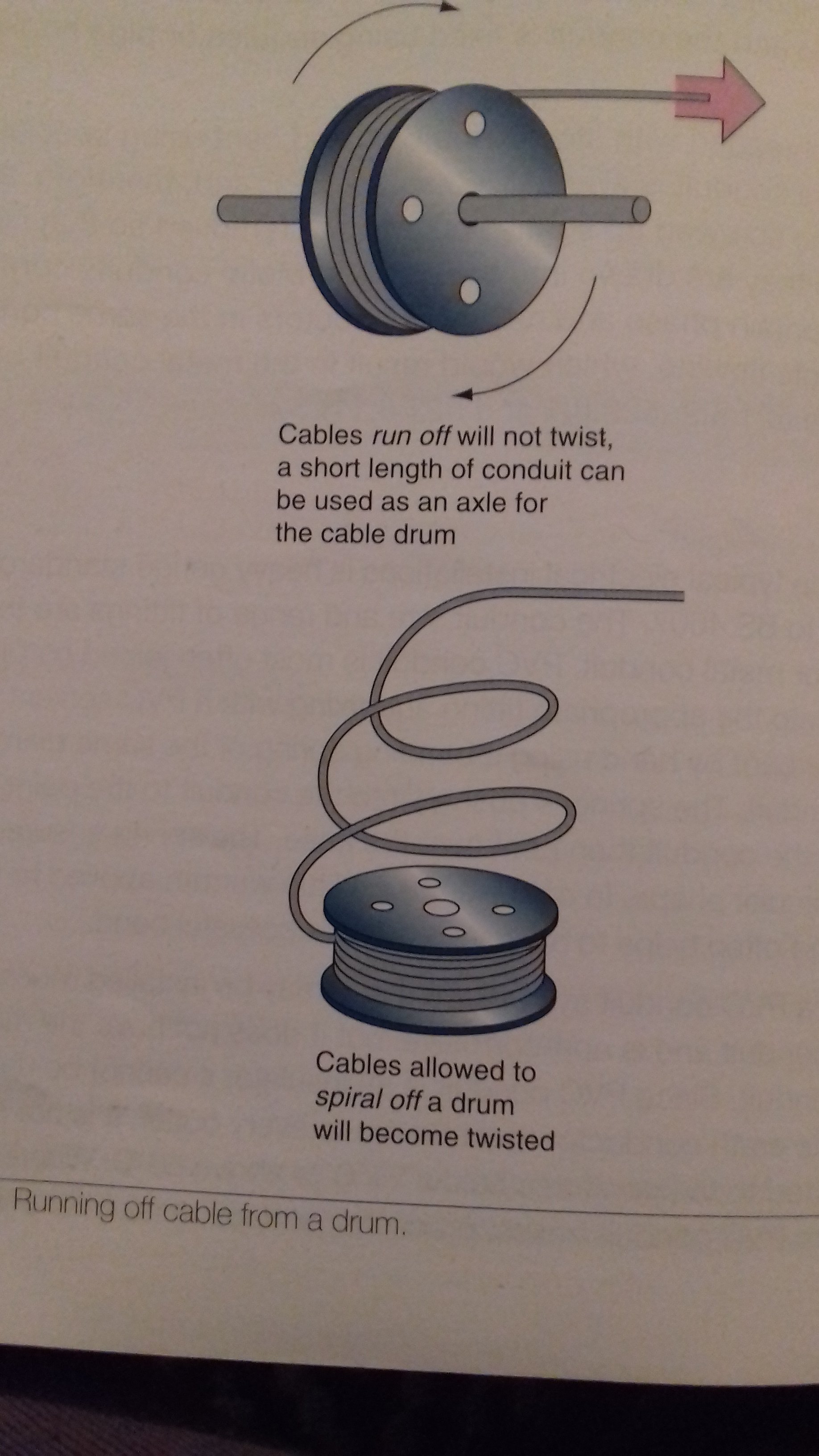

It wasn't the OSG or bs7671 where I saw something written about it, it was the BASIC electrical installation work book I got in college hahaa.

Apparently it was speaker wire they were using, just looked like flat t+e. But funnily enough, when we were ripping out the old cable, the old speaker wire WAS t+e. Not as bad as wiring lighting circuits with speaker wire I suppose, like I seen on a rewire one time.

It's not just the young ones either, always pulling cables out of joists then putting them back without twists after an older guy (50s) has been on a job yanking them through, clips all over the place, bit blind he is. One time when looking for a bit of 3-core in a stud wall he saw the edge of some plasterboard and swore that was it.

Apparently it was speaker wire they were using, just looked like flat t+e. But funnily enough, when we were ripping out the old cable, the old speaker wire WAS t+e. Not as bad as wiring lighting circuits with speaker wire I suppose, like I seen on a rewire one time.

It's not just the young ones either, always pulling cables out of joists then putting them back without twists after an older guy (50s) has been on a job yanking them through, clips all over the place, bit blind he is. One time when looking for a bit of 3-core in a stud wall he saw the edge of some plasterboard and swore that was it.

There won't be a problem with eddy currents, twists just make the cable snag as it's pulled which can cause it to become damaged. CAT5 (screened preferrably) makes far superior speaker wire than flat twin electrical cable. Much better frequency response and a hell of a lot cheaper as well

I can't imagine there would be any regulations on pulling a cable off the drum, same as you won't find a regulation on which end of a hammer to hold.....surely common sense would have a factor in it? From the sounds of the guys the OP spoke of, they don't have a clue on installation!

But I would rather be a hammer than a nail.I can't imagine there would be any regulations on pulling a cable off the drum, same as you won't find a regulation on which end of a hammer to hold.....surely common sense would have a factor in it? From the sounds of the guys the OP spoke of, they don't have a clue on installation!

T

Toneyz

It is not the old ways Pete, it's installing the cable in a professional manor flat as it comes off the drum.I agree Murdoch, I believe the old ways should be talked about when you do your training, as you must know some times cable reels can be a pain, with cable coming off when pulling cable runs in from a distance.

Absolutely!But I would rather be a hammer than a nail.

CAT5 (screened preferrably) makes far superior speaker wire than flat twin electrical cable.

Don't think I'd use it for high power work. Many of the speaker circuits I install need 2.5mm² minimum, 4.0 for longer runs to maintain damping factor, response and minimise loss. The effect on frequency response is very modest and depends mainly on how the speaker load impedance varies with frequency, e.g. nominal 8 ohm speaker might vary from 5 to 30 ohms over its useful range. Where the speaker impedance dips there will be more attenuation as the cable contributes a greater fraction of the impedance, and less where the speaker impedance peaks. Keeping the resistance down minimises this effect, and speakers are usually designed to be driven by a negligible source impedance, so more copper is usually better. High power 8 or 16 ohm speaker circuits can also exceed 50V.

How did we do it so neatly all those years ago,with no reel cable toys,it’s a doddle le,personally it’s great to have 2 or 3 drums on the go,but hey,it’s fine without the cable reeler,never had any trouble,but I have seen others get in a right state

Regulation your having a laugh ha ha ha

Regulation your having a laugh ha ha ha

S

Squid

Bit of conduit a pair of steps and 10 rolls of single 2.5mm

Leave the roll flat on the floor and pull the cable hard so the roll spins around and the cable un-furls, the worst is when it gets wet and the card board rings fall off as then that is where all the wrist action learnt as a 16 year old comes in handy un-rolling the cable reel.

Still a mystery to me how many younger Electrician and Installers can't run a length of twin and cpc without a cable roller without getting any twists, still I suppose that's the penalty you have to pay when training and only using a couple of feet of cable.

Leave the roll flat on the floor and pull the cable hard so the roll spins around and the cable un-furls, the worst is when it gets wet and the card board rings fall off as then that is where all the wrist action learnt as a 16 year old comes in handy un-rolling the cable reel.

I was taught to : lay the drum on it's side take the cable off the drum using both hands, take as much as you think is required, and then run it out on the floor, very difficult to explain, with out pictures, don't ask me to draw it out either.Bit of conduit a pair of steps and 10 rolls of single 2.5mm

Leave the roll flat on the floor and pull the cable hard so the roll spins around and the cable un-furls, the worst is when it gets wet and the card board rings fall off as then that is where all the wrist action learnt as a 16 year old comes in handy un-rolling the cable reel.

S

Squid

Or hold cable in hand and kick drum away was another way.I was taught to : lay the drum on it's side take the cable off the drum using both hands, take as much as you think is required, and then run it out on the floor, very difficult to explain, with out pictures, don't ask me to draw it out either.

I get what you mean though, remember there is always a quicker and a better way of doing something and I was good at that, maybe its my OCD lol

A cable real is cheap, and there's no excuse not to use one

But I haven't got enough room in my van Murdoch!!

A question, when using stands for reels do you roll the cable from the top or the bottom of the reel?

I know what I would do.............

Depends where they are going... if they are going up into a wall, from the bottom... if they are going down into a void below the drum, from the top

For larger drums, two vans side by side and both sets of windows open and a scaffold pole

For larger drums, two vans side by side and both sets of windows open and a scaffold pole

We once bent a scaff pole like it was a pipe cleaner with a large drum. We had to nip off to the nearest fab shop and picked up a rod of the same diameter as a scaff pole but solid steel. That worked better

I have only done the above once years ago between two bashed escort vans, used a couple of G clamps to stop the drum damaging the doors

I was doing a job a few weeks ago, I had a second man sent with me to do some of the humping and dumping. He's one of our FLM engineers, first line maint. I good analogy I like to use is half of them can't tie their own shoe laces, the other half don't want to.

We carried over three 50m reels of 25mm singles to the cabin we we're working in and chucked them on the cable jack I had. I told him to tape the ends together so we could feed them into the overhead basket we were working on and I disappeared into the cabin and go up the steps ready to start pulling the cables in.

He appeared at the door and passed me the first few meters for me to make a start, I told him to try and keep the cables from twisting together to make dressing in easier.

He was struggling a bit to feed them in so after a couple of minutes I got down and stepped outside. He'd taken the reels off the cable jack and rolled them out in the compound to make life easier...

I started calling him Hovis after that, Thick cut...

We carried over three 50m reels of 25mm singles to the cabin we we're working in and chucked them on the cable jack I had. I told him to tape the ends together so we could feed them into the overhead basket we were working on and I disappeared into the cabin and go up the steps ready to start pulling the cables in.

He appeared at the door and passed me the first few meters for me to make a start, I told him to try and keep the cables from twisting together to make dressing in easier.

He was struggling a bit to feed them in so after a couple of minutes I got down and stepped outside. He'd taken the reels off the cable jack and rolled them out in the compound to make life easier...

I started calling him Hovis after that, Thick cut...

Don't there are any reel regulationsHow did we do it so neatly all those years ago,with no reel cable toys,it’s a doddle le,personally it’s great to have 2 or 3 drums on the go,but hey,it’s fine without the cable reeler,never had any trouble,but I have seen others get in a right state

Regulation your having a laugh ha ha ha

Never use T&E or CAT5/6 for speaker wire. Typically stranded double insulated 1.0mm minimum for background music systems (100v). Minimum 1.5mm double insulated for low impedance with runs up to say 20m. For long runs on high powered consult signal loss charts. Try to use black/red conducters to aid identification.

Must remember that oneI was doing a job a few weeks ago, I had a second man sent with me to do some of the humping and dumping. He's one of our FLM engineers, first line maint. I good analogy I like to use is half of them can't tie their own shoe laces, the other half don't want to.

We carried over three 50m reels of 25mm singles to the cabin we we're working in and chucked them on the cable jack I had. I told him to tape the ends together so we could feed them into the overhead basket we were working on and I disappeared into the cabin and go up the steps ready to start pulling the cables in.

He appeared at the door and passed me the first few meters for me to make a start, I told him to try and keep the cables from twisting together to make dressing in easier.

He was struggling a bit to feed them in so after a couple of minutes I got down and stepped outside. He'd taken the reels off the cable jack and rolled them out in the compound to make life easier...

I started calling him Hovis after that, Thick cut...

Like these?Still got me old set made up of 25mm Galv! Folds up nicely too! Must be atleast 15 years old.

you only need to do that for RFC cables, so you can measure your R1+R2. then you uncoil it and fit it straight.If there is ignorance around about reeling cable off a drum,what chance these same folk coiling a cable in the figure of eight

Is exactly what I was thinking, and what I did before I bought one of those pesky A frame spoolers most merchants seem to have. Not that they're ideal in every situation. Sometimes the kick method works perfectly adequately.Broom handle, two chairs and a doorway.

That said, a cable mate and a scaffold pole works wonders too.

Only it the cable drum has a big enough center hole. Crikey how much longer is this thread going on? it's only about taking cable off of a reel properly, maybe they should start teaching the basics at these wonder spark establishments.Is exactly what I was thinking, and what I did before I bought one of those pesky A frame spoolers most merchants seem to have. Not that they're ideal in every situation. Sometimes the kick method works perfectly adequately.

That said, a cable mate and a scaffold pole works wonders too.

Similar threads

- Replies

- 5

- Views

- 585

- Replies

- 0

- Views

- 118

OFFICIAL SPONSORS

These Official Forum Sponsors May Provide Discounts to Regular Forum Members - If you would like to sponsor us then CLICK HERE and post a thread with who you are, and we'll send you some stats etc

Advert

Thread Information

- Title

- Regulation for using a cable reel?

- Prefix

- N/A

- Forum

- UK Electrical Forum

- Replies

- 40

- Unsolved

- --

Thread Tags

Advert

Thread statistics

Advert

TrueNAS JBOD Storage Server

-

-

Understanding TrueNAS JBOD Servers: A Comprehensive Guide

- Started by Dan

- Replies: 8

-