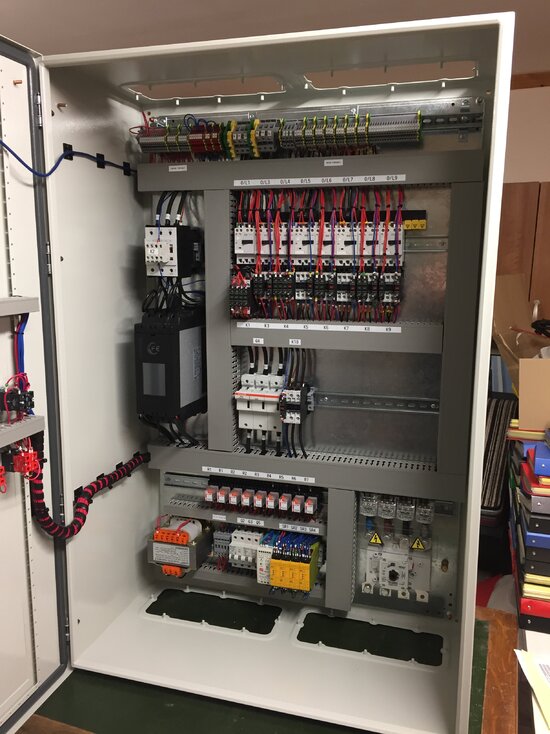

Rob, the OP has 4 off Pilz safety relays in the panel, and a single point of failure for the motor contactor, I'm surprised you haven't queried that yet?

I have to say though, I've seen a LOT worse panels from companies who are supposedly experts at panel building. A very good job.

OP: I would make sure that you do your 13849 analysis and validations though to make sure that you meet the PLr for the hazards.

A single monitored contactor, may, not be enough. If it's monitored which it seems to be, then make sure that it's force guided, along with the auxiliaries, and that they are direct acting, and mechanically linked to the main contacts.

Oh and remember clause 13.1.1 in EN 60204-1 with regard to cable entries into the top of enclosures...

It's not worded like that, but if you read it, you should see what I mean.