We still learn about that at work during human factors training pretty sure every screw was either the wrong length and/or diametersmaller issues are often unreported for small private aircraft, the bigger ones it is harder to hide when you put the wrong size screws in the windscreen!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I bet it's part of the standard syllabus of "how not to do it" British Airways Flight 5390 - WikipediaWe still learn about that at work during human factors training pretty sure every screw was either the wrong length and/or diameter

Wikipedia also has a list of explosive decompression events - not just limited to aircraft. The 1983 diving bell/decompression suite accident is not one to read when about to sit down for a meal - or if squeamish.

In my line of work, we have similar sessions. Decompression is rarely a topic, the reverse is sometimes. There was some discussion around the office in June ... There have been others, USS Thresher being one that caused a rethink around design/safety standards.

- Oct 17, 2011

- 5,313

- 4,858

- 144,758

- If you're a qualified, trainee, or retired electrician - Which country is it that your work will be / is / was aimed at?

- France

- What type of forum member are you?

- Other

- If other, please explain

- Retired Engineer

And the HMS Thetis accident caused all HMS subs to be fitted with a Thetis clip on the torpedo tubes, as did the (I think) the HMS Truculent colliding with an oil tanker making it mandatory to have a Truculent light on the bow when surfaced.

- Aug 12, 2017

- 14,335

- 20,734

- 3,557,381

- 51

- If you're a qualified, trainee, or retired electrician - Which country is it that your work will be / is / was aimed at?

- United Kingdom

- What type of forum member are you?

- Practising Electrician (Qualified - Domestic or Commercial etc)

So the warning light, or incident is named after the vessel that an accident happened to??

What happened to the HMS What-does-this-button-do?

What happened to the HMS What-does-this-button-do?

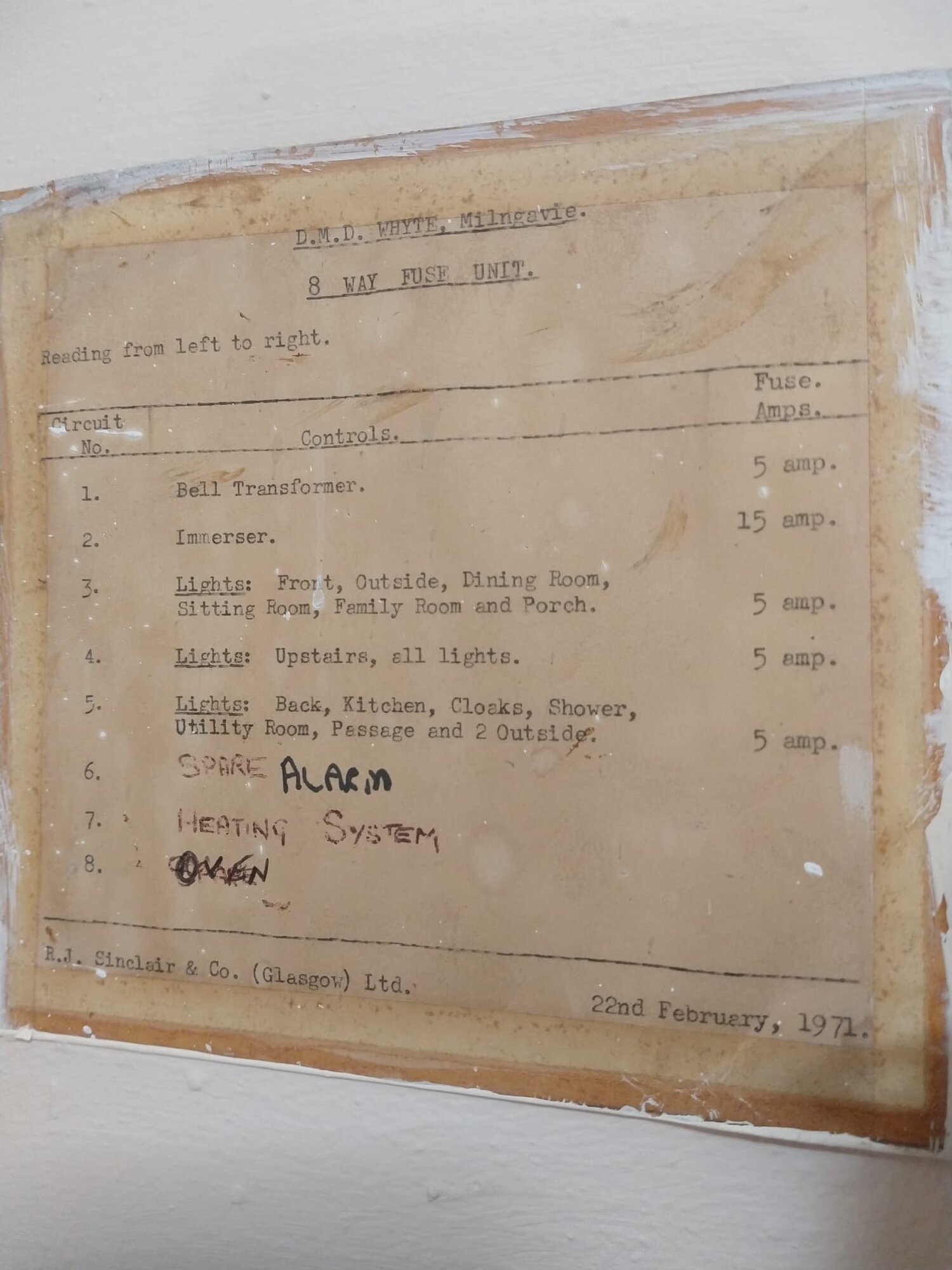

Just a small job, replacing a 3 gang switch that was basically worn out...brushed steel, no fly-lead to backbox, and a mix of t&e and a flex...nice switch with the coms all at the top and L1 and L2 at the bottom, rather than the staggered pattern of the new switch...it all went swimmingly (DIF!)...here is a nice touch though, the original electrician typed out a nice key to what was what...

All very neat and self-explanatory, one 15A and the rest 5A...

and a very neat board too

All very neat and self-explanatory, one 15A and the rest 5A...

and a very neat board too

N

nicebutdim

Fitted a modern version of that bell a few days back. Lots of noise and takes up very little space.

You know that time when you take a pic of the wiring, replicate it, even though the new switch is configured differently, connect it all up...and each switch does what it's supposed to do...then you realise it's upside down, so on is up and off is down, so you rotate the switch...all is good til she says "Oh, the left one is supposed to operate the lights on the right, and the right one is supposed to do the left ones..." and i said, "the middle one does the middle string, so that's good!" She wanted it back the way it was...so I undid the outer two and swapped them over, checked they were working, and all was well. I added a fly-lead from the chrome switch to the back-box, screwed it all back and...BANG! Yup, nipped a cable with the fixing screw...a couple of seconds of sparks and glows and the fuse blew...that's the fuse number 5, lighting, 5Amp...no, it's not, all the 5A fuses, which are in 15A carriers, are fitted with 15A fusewire...still, I'm glad the faceplate was earthed. Another 5 minute job, satisfactorily completed! Spot the nice curly tails from the bottom of the box!

Never mind...

"Oh, while you are here..."

FEK, what now?

This under-cupboard light isn't working...

never seen one before, but hey...finally worked out how to take out the lamp from the holder, and it's a GX53. Oddly enough, I don't have a spare in my bag...research shows that the 2.5W 6500k version she has is impossible to source...

I';ve ordered a 4 pack of 6W warm white...she'll never notice if i replace them all at once!

Never mind...

"Oh, while you are here..."

FEK, what now?

This under-cupboard light isn't working...

never seen one before, but hey...finally worked out how to take out the lamp from the holder, and it's a GX53. Oddly enough, I don't have a spare in my bag...research shows that the 2.5W 6500k version she has is impossible to source...

I';ve ordered a 4 pack of 6W warm white...she'll never notice if i replace them all at once!

N

nicebutdim

This under-cupboard light isn't working...

never seen one before, but hey...finally worked out how to take out the lamp from the holder, and it's a GX53. Oddly enough, I don't have a spare in my bag...research shows that the 2.5W 6500k version she has is impossible to source...

I';ve ordered a 4 pack of 6W warm white...she'll never notice if i replace them all at once!

Think I'd have aimed to replace the lot with slim link lights and amazed her with instant full illumination.

N

nicebutdim

Here we are. I reckon this is all any house needs.

Does the job well, cheap to buy and no integrated camera or spyware.

Does the job well, cheap to buy and no integrated camera or spyware.

I did that for my neighbour and she was delighted! Robus spear lamps, really nice. The old brown and beige fluorescent ones had melted end caps and had charred the underside of the cabinets...

12 of them replaced by 3 new ones...what a transformation!

12 of them replaced by 3 new ones...what a transformation!

and of no connection to any of this, I'm off to Stranraer tomorrow, via Portpatrick, for a couple of days at the Stranraer Oyster Festival...

Have a nice weekend!

Have a nice weekend!

N

nicebutdim

I did that for my neighbour and she was delighted! Robus spear lamps, really nice. The old brown and beige fluorescent ones had melted end caps and had charred the underside of the cabinets...

12 of them replaced by 3 new ones...what a transformation!

Even the cheap LAP ones from Screwfix seem fairly reliable. I've put a few sets in on occassions where price was a big issue for someone elderly. Not heard of a single failure to date and everyone has been pleased with the difference between old and new.

LAP certainly wouldn't be a 'go to' or recommendation, but they do seem to be okay.

N

nicebutdim

and of no connection to any of this, I'm off to Stranraer tomorrow, via Portpatrick, for a couple of days at the Stranraer Oyster Festival...

Have a nice weekend!

Never been to Portpatrick by road. Quickest route from here is over water.

Come to think of it, the same applies to Stranraer.

- Jun 9, 2013

- 6,339

- 4,266

- 10,250,798

- If you're a qualified, trainee, or retired electrician - Which country is it that your work will be / is / was aimed at?

- United Kingdom

- What type of forum member are you?

- Practising Electrician (Qualified - Domestic or Commercial etc)

Was going to say that fuse box is nothing like the schedule draw upYou know that time when you take a pic of the wiring, replicate it, even though the new switch is configured differently, connect it all up...and each switch does what it's supposed to do...then you realise it's upside down, so on is up and off is down, so you rotate the switch...all is good til she says "Oh, the left one is supposed to operate the lights on the right, and the right one is supposed to do the left ones..." and i said, "the middle one does the middle string, so that's good!" She wanted it back the way it was...so I undid the outer two and swapped them over, checked they were working, and all was well. I added a fly-lead from the chrome switch to the back-box, screwed it all back and...BANG! Yup, nipped a cable with the fixing screw...a couple of seconds of sparks and glows and the fuse blew...that's the fuse number 5, lighting, 5Amp...no, it's not, all the 5A fuses, which are in 15A carriers, are fitted with 15A fusewire...still, I'm glad the faceplate was earthed. Another 5 minute job, satisfactorily completed! Spot the nice curly tails from the bottom of the box!

Never mind...

"Oh, while you are here..."

FEK, what now?

This under-cupboard light isn't working...

never seen one before, but hey...finally worked out how to take out the lamp from the holder, and it's a GX53. Oddly enough, I don't have a spare in my bag...research shows that the 2.5W 6500k version she has is impossible to source...

I';ve ordered a 4 pack of 6W warm white...she'll never notice if i replace them all at once!

- Feb 26, 2013

- 1,039

- 1,036

- 1,688

- 45

- If you're a qualified, trainee, or retired electrician - Which country is it that your work will be / is / was aimed at?

- United Kingdom

- What type of forum member are you?

- Practising Electrician (Qualified - Domestic or Commercial etc)

- Dec 9, 2008

- 13,496

- 18,280

- 3,557,381

- If you're a qualified, trainee, or retired electrician - Which country is it that your work will be / is / was aimed at?

- United Kingdom

- What type of forum member are you?

- Other

- If other, please explain

- C&G 17th edition regs

C&G 2382-18 (18th edition regs)

C&G 2394 Inspection & Test

C&G PAT

2 x BPEC electrical courses/exams

Can't believe he did that. He must not have even looked at the other side of the wall before drilling. Or a big misjudgement!

- Feb 26, 2013

- 1,039

- 1,036

- 1,688

- 45

- If you're a qualified, trainee, or retired electrician - Which country is it that your work will be / is / was aimed at?

- United Kingdom

- What type of forum member are you?

- Practising Electrician (Qualified - Domestic or Commercial etc)

lol He said his apprentice measured it! He must have realised something was wrong by the depth surely! he actually asked me if i could move it all so he could still put his overflow pipe there, cheek!Can't believe he did that. He must not have even looked at the other side of the wall before drilling. Or a big misjudgement!

I was drilling through the other day and measured extremely carefully to avoid a gate post and a gas pipe. The pilot hole went fine and it came out exactly where I wanted. Then I went up a size and felt the two skins, but then a bit of air and then something 'strange'. I stopped when it was clear this wasn't brick and and went to look.lol He said his apprentice measured it! He must have realised something was wrong by the depth surely! he actually asked me if i could move it all so he could still put his overflow pipe there, cheek!

The builders lad had opened the gate! But the brick I'd put there to keep it closed was now blocking the frame so the gate couldn't close and the drill was in the process of taking a nice little gouge out of the gate. Luckily this wasn't very noticeable as the gate was rotten beyond hope anyway.

BG strikes againfew pictures from my recent jobs

Plumber didnt check the other side of the wall before drilling through(had a lucky escape though) and a recent CU change that leaves alot to be desired

OFFICIAL SPONSORS

These Official Forum Sponsors May Provide Discounts to Regular Forum Members - If you would like to sponsor us then CLICK HERE and post a thread with who you are, and we'll send you some stats etc

Advert

YOUR Unread Posts

-

DNO, EV installer, house fuse many cables and not a clue

- Latest: brianmoooore

-

-

-

-

-

-

-

-

Thread Information

- Title

- Dodgy trade pictures for your amusement! - 1 Million Views!

- Prefix

- N/A

- Forum

- UK Electrical Forum

- Replies

- 8K