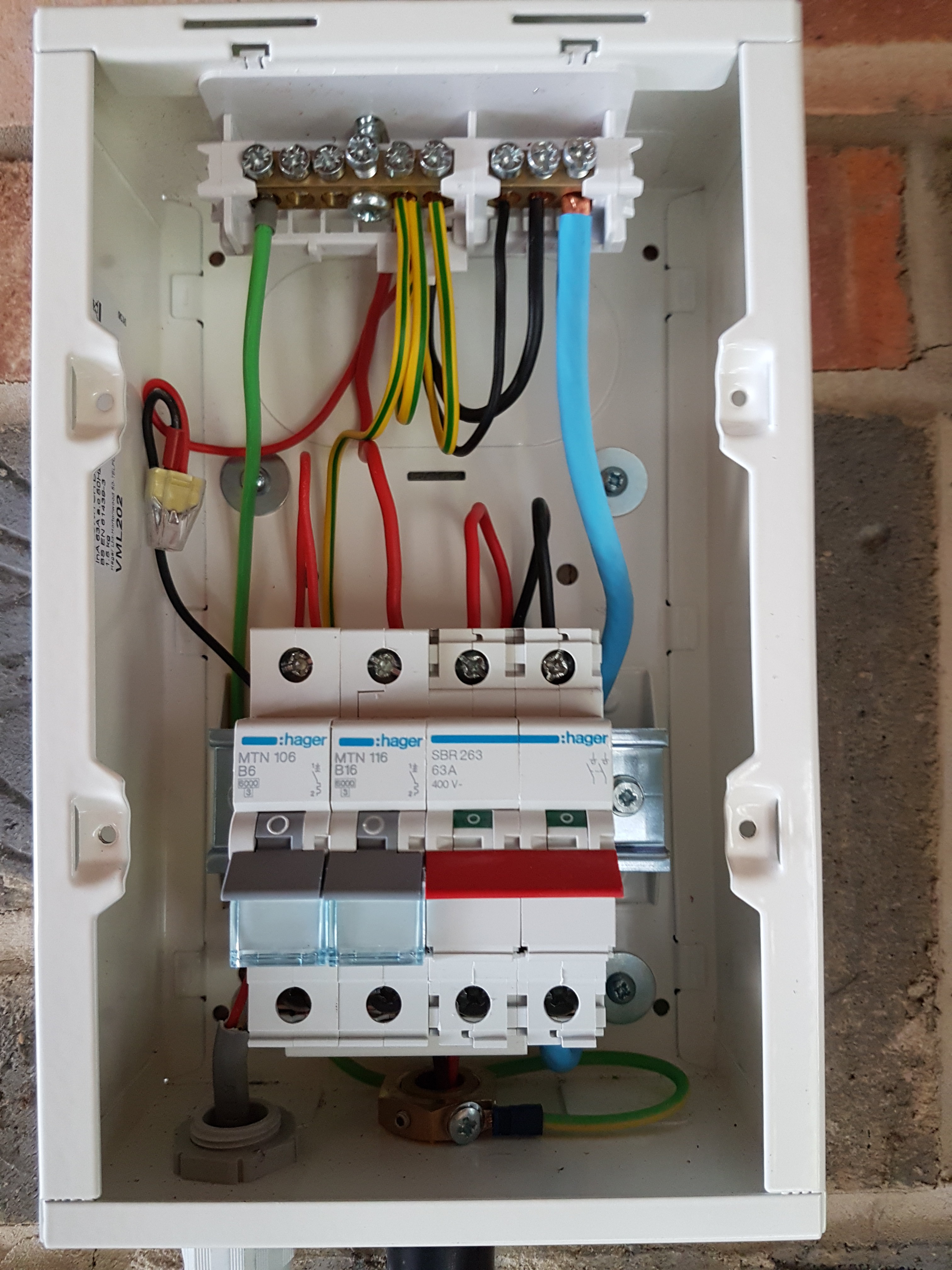

It is often said on here we criticise others work without having the conviction to show our own work. We have Dodgy Trade Pics For Your Enjoyment so let's show the other side. No job too small or to big, before or after let's see 'em. I can change the header if someone can think of a better one. I shall start the ball rolling with this considerable board change I did today