Hi

I am trying to create a thermal cutout circuit to protect a large (10sqm) silicone heat pad table. The total heat pad load is around 30A (split between seven 1kW heat pads), running off a single phase 32A supply. The heaters are controlled with Eurotherms and SSRs, which fail in the closed position. Because of this I want to add thermal switches, but in a manually-resetting circuit. Due to the size of the table, the switches will be very hard to reach (wedged underneath a 500kg steel plate), hence why I dont want to just use thermal fuses.

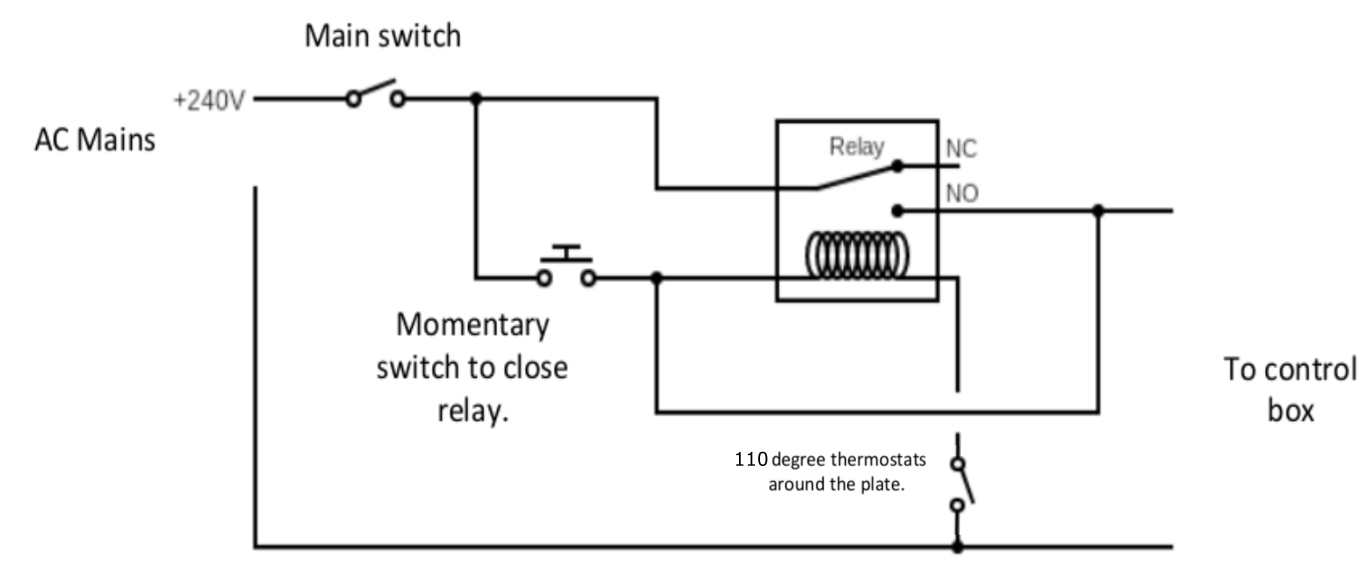

The max table temp is 90deg, so I was planning to use 110deg switches to switch off the power to the control box via a power relay, the power relay is initially switched on by use of a momentary switch. Once the relay is closed, the coil is powered by the mains supply, until a thermal switch breaks this circuit and powers off the relay. The control box will then not power back on until the thermal switches have closed again, and the momentary switch is manually pressed. See diagram below.

However, I cannot find a power relay to these specs. The link below is the closest I could find, but contact rating is only 30A.

I am slightly worried that the right components don't exist because my design is wrong in some way. So if anyone can help with the correct components or a new design that would be amazing.

Thanks

I am trying to create a thermal cutout circuit to protect a large (10sqm) silicone heat pad table. The total heat pad load is around 30A (split between seven 1kW heat pads), running off a single phase 32A supply. The heaters are controlled with Eurotherms and SSRs, which fail in the closed position. Because of this I want to add thermal switches, but in a manually-resetting circuit. Due to the size of the table, the switches will be very hard to reach (wedged underneath a 500kg steel plate), hence why I dont want to just use thermal fuses.

The max table temp is 90deg, so I was planning to use 110deg switches to switch off the power to the control box via a power relay, the power relay is initially switched on by use of a momentary switch. Once the relay is closed, the coil is powered by the mains supply, until a thermal switch breaks this circuit and powers off the relay. The control box will then not power back on until the thermal switches have closed again, and the momentary switch is manually pressed. See diagram below.

However, I cannot find a power relay to these specs. The link below is the closest I could find, but contact rating is only 30A.

I am slightly worried that the right components don't exist because my design is wrong in some way. So if anyone can help with the correct components or a new design that would be amazing.

Thanks