Hi all

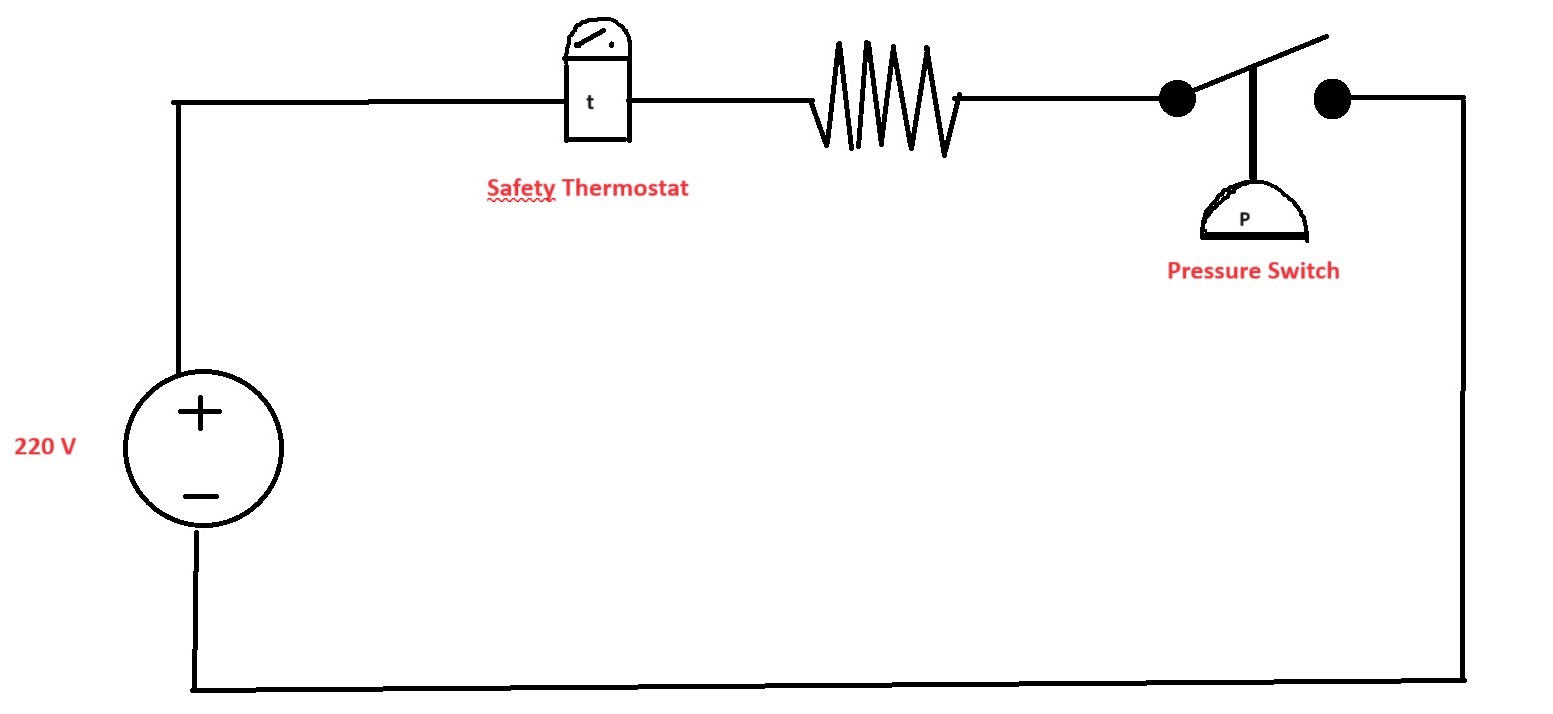

I have a professional coffe machine working at 220 V and it currently drain about 2,5 kW of power. I have made this simple and horrible schematic here just to explain how it works:

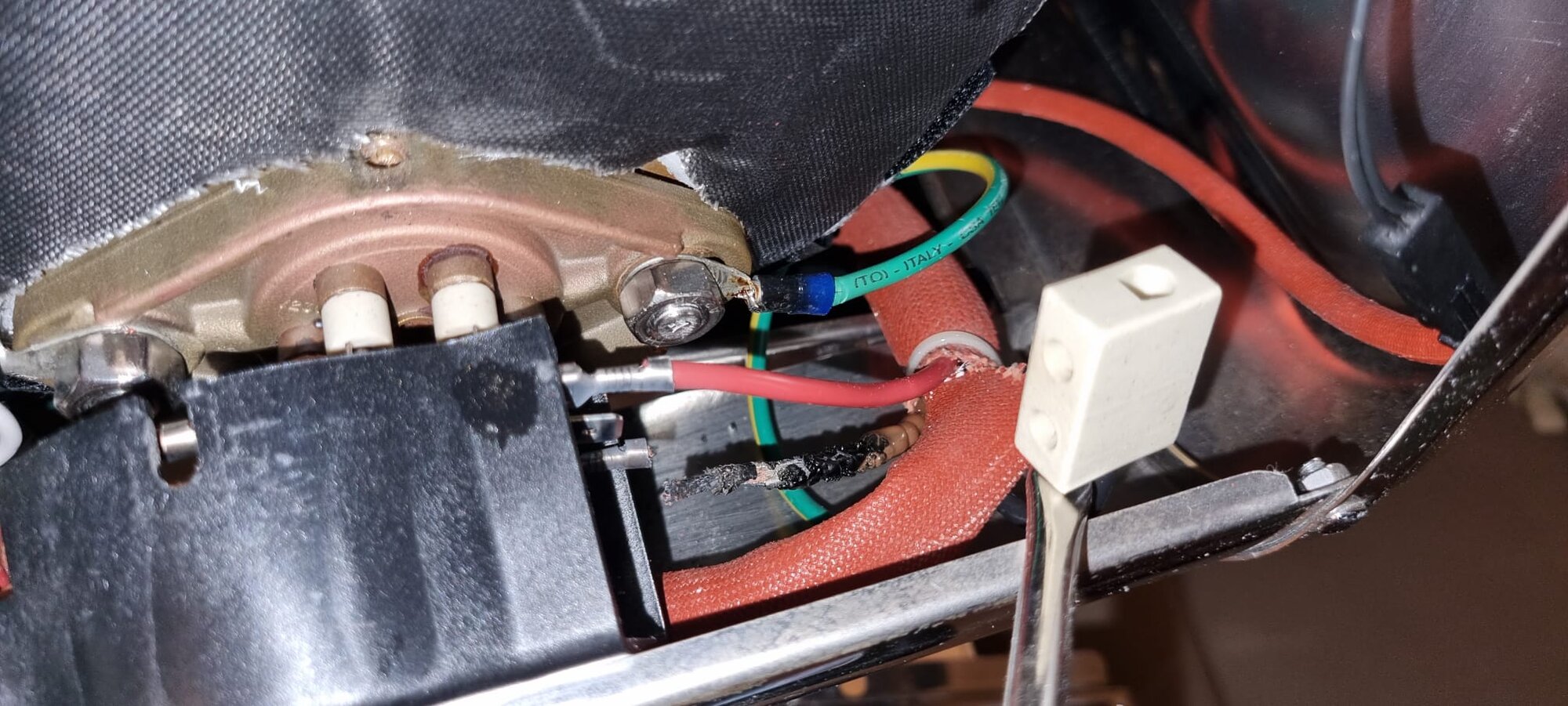

Some time ago I changed the fastons on the resistance from brass faston to stainless steel faston and some time after, this is what happen:

As you can see the wire on the bottom is completely burned and as I did not notice that immediately also the general switch and the safety thermostast get damage. So I changed the general switch, the safety thermostat and cutted the burned wire so I put everything back toghether.

I did a full restoration of the machine but I did not change the eletrical wires because they looked good ( they are industrial ones and have a 2.5 mm^2 section ) even if they hare 20 years old now.

Now this happen again on the other side:

I'm wondering if this can be related to the stainless steel material of the faston that maybe can produce and overheating due to the fact that the electrical condutivity of the stainless steel it's worst then the one of the brass faston. This never happen with brass faston. So what do you think?

I have a professional coffe machine working at 220 V and it currently drain about 2,5 kW of power. I have made this simple and horrible schematic here just to explain how it works:

Some time ago I changed the fastons on the resistance from brass faston to stainless steel faston and some time after, this is what happen:

As you can see the wire on the bottom is completely burned and as I did not notice that immediately also the general switch and the safety thermostast get damage. So I changed the general switch, the safety thermostat and cutted the burned wire so I put everything back toghether.

I did a full restoration of the machine but I did not change the eletrical wires because they looked good ( they are industrial ones and have a 2.5 mm^2 section ) even if they hare 20 years old now.

Now this happen again on the other side:

I'm wondering if this can be related to the stainless steel material of the faston that maybe can produce and overheating due to the fact that the electrical condutivity of the stainless steel it's worst then the one of the brass faston. This never happen with brass faston. So what do you think?