-

Pro's OnlyElectricians Arms Electrician Talk How to Access The Arms Domestic Electrician Industrial Electricians Wiring, Theories, Regulations Engineering Chat Periodic Testing Problems Electricians Downloads Commercial Electricians Security (Access-Only) Access Private Area Business Related Advice Certification Schemes Electrical & PAT Testing

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

E

Earthstore

Hmmm, Bonding any array will not stop it working, however in certain circumstances it is a requirement.

If SMA say it requires bonding, then I would say it requires bonding.

If SMA say it requires bonding, then I would say it requires bonding.

W

wstevew

Exactly,

Nothing that a pair of wire cutters wouldn't fix.

What puzzles me is, their Techinical guy and SMA suggested bonding the array may solve the problem. I know bonding the array is a subjective thing.

How could bonding the array frame stop a 4000TL and Suntech panels from working?

Nothing that a pair of wire cutters wouldn't fix.

What puzzles me is, their Techinical guy and SMA suggested bonding the array may solve the problem. I know bonding the array is a subjective thing.

How could bonding the array frame stop a 4000TL and Suntech panels from working?

W

wstevew

When I originally emailed SMA about the 601 errors they responded with

This can be caused by a number of things. certainly in the first instance. I would suggest that you check with your installers to check that your array has been correctly bonded to earth. they should be able to source the correct bonding information from the manufacturer of the frame.

This can be caused by a number of things. certainly in the first instance. I would suggest that you check with your installers to check that your array has been correctly bonded to earth. they should be able to source the correct bonding information from the manufacturer of the frame.

E

Earthstore

Bonding and earthing are two separate things, something that appears to cause confusion,

Bonding is when you join two conductive materials together, like the copper pipes under your sink.

Earthing is when you take a wire back to an earthing point, and with most (not all) PV systems, this would be to a metal rod in the ground.

So it sounds like your system needs bonding and earthing, not really too difficult or expensive if they are already up there.

I hope this helps.

Bonding is when you join two conductive materials together, like the copper pipes under your sink.

Earthing is when you take a wire back to an earthing point, and with most (not all) PV systems, this would be to a metal rod in the ground.

So it sounds like your system needs bonding and earthing, not really too difficult or expensive if they are already up there.

I hope this helps.

W

wstevew

Thats what I thought, but they are saying it will stop the system working. The office are also trying to put me off by putting the responsibility on me, by saying they will do it but the consequences are down to me.

E

Earthstore

In most cases earthing is for safety, but for a TL inverter it can be a requirement to make the system work correctly, your system had a fault, SMA recommended a solution, as the company installed an SMA inverter (good choice in my opinion) they should connect it how SMA recommend, simple.

Tell them to do it, if it does not work, (which it will) you can always cut the wire off.

Tell them to do it, if it does not work, (which it will) you can always cut the wire off.

Bonding and earthing are two separate things, something that appears to cause confusion,

Bonding is when you join two conductive materials together, like the copper pipes under your sink.

Earthing is when you take a wire back to an earthing point, and with most (not all) PV systems, this would be to a metal rod in the ground.

So it sounds like your system needs bonding and earthing, not really too difficult or expensive if they are already up there.

I hope this helps.

Both bonding and earthing should eventually be connected to the main earthing terminal - supplementary bonding is just an extension of this.

Earthing works by keeping disconnection times as short as possible, bonding is concerned with the magnitude of any shock - if the all metalwork is at an equipotential then there should be no voltages present between them under fault conditions.

As PV panels and the frames have no disconnection devices in the system then earthing is irrelevant.

But as Gavin A points out earlier in this thread, this may not be an issue in terms of complying with guidelines anymore - although if SMA are saying it then it certainly can't hurt to do so.

Tell the installers that you would rather it was bonded as SMA have requested it. Then, if for some reason it stops working, it can always be disconnected (preferably from both ends)

Tell the installers that you would rather it was bonded as SMA have requested it. Then, if for some reason it stops working, it can always be disconnected (preferably from both ends)

E

Earthstore

Both bonding and earthing should eventually be connected to the main earthing terminal - supplementary bonding is just an extension of this.

Earthing works by keeping disconnection times as short as possible, bonding is concerned with the magnitude of any shock - if the all metalwork is at an equipotential then there should be no voltages present between them under fault conditions.

As PV panels and the frames have no disconnection devices in the system then earthing is irrelevant.

I agree with the above, apart from on a pV system, if there is a slight leakage it needs a path to discharge, IE an Earth, this is not about disconnection times.

Also, if you can not touch the system from the equipotential zone, (ie velox) then you should earth to a rod, otherwise you could be bringing a potential into the zone.

This is my understanding anyway.

W

wstevew

He is saying that he will bond it to the AC Isolator, it has 2.5mm Is that correct?

E

Earthstore

Are you saying the AC cable is 2.5 TWE cable?

Just bang a rod in the ground and earth it to that.

Please read my post above about importing a potential.

Ihope this helps

Just bang a rod in the ground and earth it to that.

Please read my post above about importing a potential.

Ihope this helps

W

wstevew

When I said about running a cable down the the earth point where the meter is. He said there is TWE already running from the loft and he would run the bonding to the AC Isolator.

W

wstevew

Does this look better?

- - - Updated - - -

Oh dear.

- - - Updated - - -

No, it needs to be 10mm at least.

Oh dear.

W

wstevew

They are 1 course of tiles from the eves.

the orientation of that array is east, the flue doesnt seem to affect yield.

Just been up on the flat roof and noticed that the clamps on the right side are only attached to the rail by about 2-3 mm :dizzy2:

Have just asked them to sort it out.

the orientation of that array is east, the flue doesnt seem to affect yield.

Just been up on the flat roof and noticed that the clamps on the right side are only attached to the rail by about 2-3 mm :dizzy2:

Have just asked them to sort it out.

J

JulianC

Shame they couldn't be bothered to notch the back of the tiles out so they sit flush. Wind and wind driven rain will find its way up there for sure.

They are 1 course of tiles from the eves.

the orientation of that array is east, the flue doesnt seem to affect yield.

Just been up on the flat roof and noticed that the clamps on the right side are only attached to the rail by about 2-3 mm :dizzy2:

Have just asked them to sort it out.

1 course of tiles should be about 300mm - it just looked closer than that to me.

I'm amazed that the flu doesn't affect yield. How have you worked that out?

- - - Updated - - -

Shame they couldn't be bothered to notch the back of the tiles out so they sit flush. Wind and wind driven rain will find its way up there for sure.

Just noticed that. Definitely needs sorting.

W

wstevew

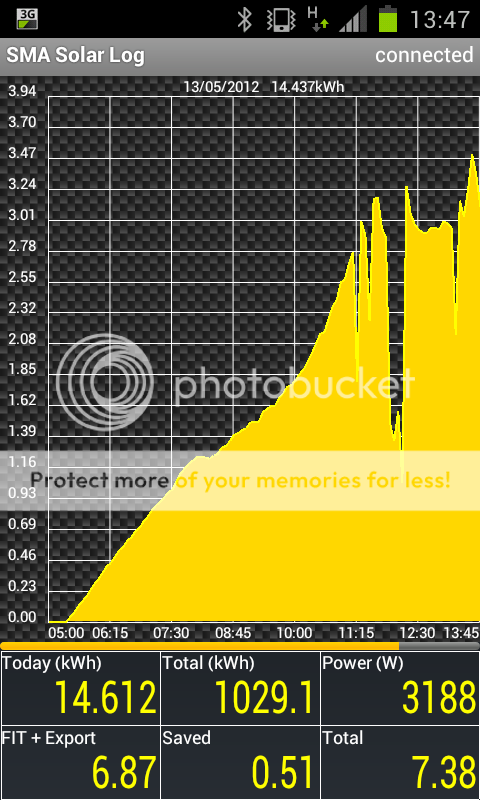

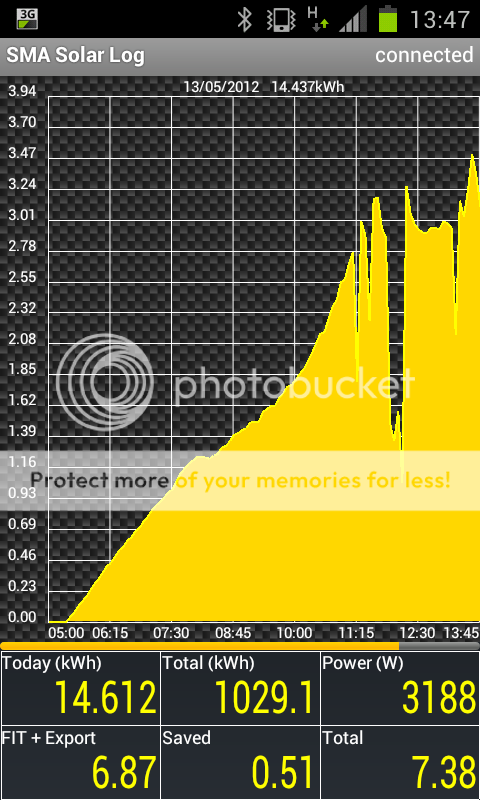

I cant be entirely sure it doesnt affect yield, but as its east the shadow is early in the morning as the sun is rising and here is a graph. I think the plateau is just before the west side starts.

Also for some of the time the shadow is cast across the frames

Also for some of the time the shadow is cast across the frames

J

JulianC

Regardless, I'd lop a foot or so off that soil pipe so it's flush with the array and stick the bird cage back on the top.

E

Earthstore

W

wstevew

I was going to chop the pipe down, it is above the bathroom window though. I hadn't bothered as there is no obvious drop on the graph. I do have the optitrack enabled.

I have asked them to notch the tiles, sort out the clamps attached to 2-3mm of rail, and tie the wires up so they don't touch the roof.

I have asked them to notch the tiles, sort out the clamps attached to 2-3mm of rail, and tie the wires up so they don't touch the roof.

B

babba

How did you manage to pick this company to do the install and when was it installed ?

W

wstevew

It wasn't my first choice. My first choice was unable to get stock as no sooner had I made the decision barking and his lot decided to cause a panic. Installed on the 25th November 2011.

They are not a huge company, but also not small, they have done some large scale solar farm type installs and domestic too. They offer other electrical work and renewables.

To their credit they seem willing to fix their errors. I just hope they fix my system.

At the time, I had a couple of local installers for whom it became unable to source stock. Then there was the double glazing type companies, and these who specialise in renewebles and electrical contracting.

They are not a huge company, but also not small, they have done some large scale solar farm type installs and domestic too. They offer other electrical work and renewables.

To their credit they seem willing to fix their errors. I just hope they fix my system.

At the time, I had a couple of local installers for whom it became unable to source stock. Then there was the double glazing type companies, and these who specialise in renewebles and electrical contracting.

Last edited by a moderator:

B

babba

I understand the pre 12 Dec madness, they seem to be draging their heels on sorting out issues but good luck.

W

wstevew

I was asked to check if this was Ok now. Not so good.

W

wstevew

They just said they will run a 4mm Bonding to where the meter is. I asked them to check as I thought it should be 10mm.

will 4mm be ok, or is that dangerous?

will 4mm be ok, or is that dangerous?

dansk

-

Hi - we can all slate others work - but im talking with my hat of here - i would seriously ask them to re-scaff, remove all the panels and start again, its not good my friend from photos your showing on here. All they need to do is start over and make it right, the tiles are kicking up too far, it looks like they broke another one and used lead flashing to cover it up, brackets no straight, connecting rail gap too large. You paid your money and you deserve better.

Ive had my problems don't get me wrong, and ive had to taste my own medicine - resurrect scaffold and re-do a job, but i know its right now.

Ive had my problems don't get me wrong, and ive had to taste my own medicine - resurrect scaffold and re-do a job, but i know its right now.

W

wstevew

dansk,

scaffold is up on other side. this is the re-fit. and he now tells me to notch the tiles he will have to take it all off again. they have done the same on the west side where the scaffold is up.

unbelievable. they move all the rails and this time do not notch the tiles and say they can't without removing it all again. he says i already have a few lifted tiles anyway. So I said that I dont want any more!

scaffold is up on other side. this is the re-fit. and he now tells me to notch the tiles he will have to take it all off again. they have done the same on the west side where the scaffold is up.

unbelievable. they move all the rails and this time do not notch the tiles and say they can't without removing it all again. he says i already have a few lifted tiles anyway. So I said that I dont want any more!

W

wstevew

He said "we dont normally cut the tiles". I said but you did the first time you installed it, why would you not now.

Also now its all disturbed again the mortar on the side edge tiles is all loose.

Also now its all disturbed again the mortar on the side edge tiles is all loose.

J

JulianC

un....be.....lievable.

I truly hope you get this sorted satisfactorily wstevew. Such lazy-arsed, excuse making, incompetence really does get on my man -----. Proof if any were needed that it's not just the double glazing mob that are responsible for dragging down standards. Keep on to them until it is sorted. Bloody shower.

I truly hope you get this sorted satisfactorily wstevew. Such lazy-arsed, excuse making, incompetence really does get on my man -----. Proof if any were needed that it's not just the double glazing mob that are responsible for dragging down standards. Keep on to them until it is sorted. Bloody shower.

E

Earthstore

Why not print off the pictures I posted, and show them to them, with the words, I want mine to look like that.

I showed you the both because the correct bracket was used it did not need grinding as there was a very small gap and the tile sat down properly, and the other needed grinding as it "kicked" the tile up on the joint.

Keep on to them until it is correct, but keep making the tea.

I showed you the both because the correct bracket was used it did not need grinding as there was a very small gap and the tile sat down properly, and the other needed grinding as it "kicked" the tile up on the joint.

Keep on to them until it is correct, but keep making the tea.

W

wstevew

I find it beyond belief that they can come and move the rails and not make the tiles sit flat as they did they first time they installed it.

The installers are about to leave and I await their call.

As always thanks for your help.

The installers are about to leave and I await their call.

As always thanks for your help.

W

wstevew

Why not print off the pictures I posted, and show them to them, with the words, I want mine to look like that.

I showed you the both because the correct bracket was used it did not need grinding as there was a very small gap and the tile sat down properly, and the other needed grinding as it "kicked" the tile up on the joint.

Keep on to them until it is correct, but keep making the tea.

The amazing thing is they did look like that until today when they moved the rails.

They have just left now and say they will come back in the morning and remove it all again and grind the tiles out so they sit flush. Seems such a shame, all that hard work and they will have to do it all again just because of cutting a few corners (or not as the case may be).

They did sort out the clamps (I dont even want to think about that if I didn't notice it) and wires, but i guess they will have to do it all again in the morning.

Hopefully they will get there eventually. But it does make me wonder how many other systems...

Similar threads

- Replies

- 7

- Views

- 460

OFFICIAL SPONSORS

These Official Forum Sponsors May Provide Discounts to Regular Forum Members - If you would like to sponsor us then CLICK HERE and post a thread with who you are, and we'll send you some stats etc

Advert

Thread Information

- Title

- Position of rails/clamps

- Prefix

- N/A

- Replies

- 153

Thread Tags

Advert

Thread statistics

Advert

TrueNAS JBOD Storage Server

-

-

-

Understanding TrueNAS JBOD Servers: A Comprehensive Guide

- Started by Dan

- Replies: 8