- Jun 29, 2020

- 1,752

- 2,506

- 3,688

- If you're a qualified, trainee, or retired electrician - Which country is it that your work will be / is / was aimed at?

- United Kingdom

- What type of forum member are you?

- Practising Electrician (Qualified - Domestic or Commercial etc)

- Business Name

- Dartlec

Posting this more as a discussion than seeking advice, as I've already fixed the issue.

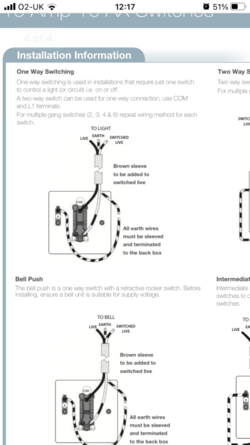

EICR on a house which at some point had been 'done up' with metal face plates for all the switches. When checked with a wander lead R2 was within spec on the ones I tested, but when taking a random one off found the earth to the back box only - so then checked them all and not a single one had been brought forward to the nice obvious earth terminal on the switch :facepalm:

I remade all the earths to the front plates anyway in this case, but was wondering what code people might give this if they found it on a job where they could not do remedials? It's sort of the opposite of the old argument about needing to earth the backbox or add a flylead.

Would people consider an adequate reading of R2 to the front of the switch when correctly installed as not needing a code? Or automatic C2 once you saw the lack of cable to the plate terminal?

In this case, one of the back boxes was metal with insulated lugs anyway, so that would have been an immediate C2. But I remade them all anyway as I was also working in the place.

Does show the limitation of R2 checks on everything, where you aren't removing every plate. Didn't help in this case that the bodger who'd done it had half buried all the plates into the wall to discourage ever removing them!

EICR on a house which at some point had been 'done up' with metal face plates for all the switches. When checked with a wander lead R2 was within spec on the ones I tested, but when taking a random one off found the earth to the back box only - so then checked them all and not a single one had been brought forward to the nice obvious earth terminal on the switch :facepalm:

I remade all the earths to the front plates anyway in this case, but was wondering what code people might give this if they found it on a job where they could not do remedials? It's sort of the opposite of the old argument about needing to earth the backbox or add a flylead.

Would people consider an adequate reading of R2 to the front of the switch when correctly installed as not needing a code? Or automatic C2 once you saw the lack of cable to the plate terminal?

In this case, one of the back boxes was metal with insulated lugs anyway, so that would have been an immediate C2. But I remade them all anyway as I was also working in the place.

Does show the limitation of R2 checks on everything, where you aren't removing every plate. Didn't help in this case that the bodger who'd done it had half buried all the plates into the wall to discourage ever removing them!