- Mar 21, 2021

- 170

- 24

- 93

- If you're a qualified, trainee, or retired electrician - Which country is it that your work will be / is / was aimed at?

- United Kingdom

- What type of forum member are you?

- DIY or Homeowner (Perhaps seeking pro advice, or an electrician)

After completing a new RFC or modifying an existing one, I will always test continuity across all 3 conductors at the Consumer unit. I use the continuity function on my Fluke 2 pole tester to do this. This is done whilst the circuit is dead.

Prior to this, I am very diligent with the conductors in each socket terminal and ensuring that I have the correct amount of cable length. I also screw the terminals tight again once the excess cable is bent in the back box and before I screw in the socket plate incase anything had come loose.

This means that when it comes to the continuity test, everything is okay. Else, I will revisit each socket, rectify and test again…

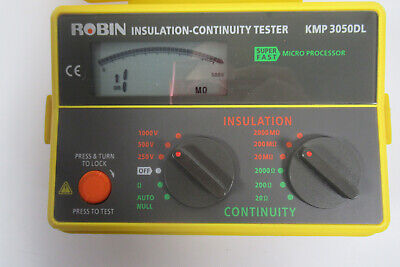

I know “proper” electricians will do R1, etc. tests using a low ohm meter. What am I missing without doing these tests and can any of these be done without buying the very expensive low ohm meters that electricians have?

I appreciate that the very simple response is that these test have to be done.

Thanks in advance.

Prior to this, I am very diligent with the conductors in each socket terminal and ensuring that I have the correct amount of cable length. I also screw the terminals tight again once the excess cable is bent in the back box and before I screw in the socket plate incase anything had come loose.

This means that when it comes to the continuity test, everything is okay. Else, I will revisit each socket, rectify and test again…

I know “proper” electricians will do R1, etc. tests using a low ohm meter. What am I missing without doing these tests and can any of these be done without buying the very expensive low ohm meters that electricians have?

I appreciate that the very simple response is that these test have to be done.

Thanks in advance.