D

Dave79

Hello everyone,

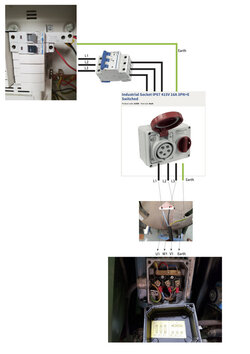

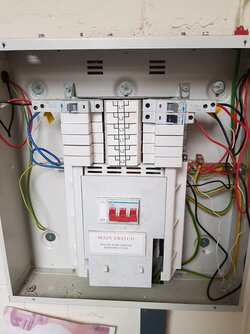

I am an artist and have a picture framing machine that is 3phase, bought it years ago and not sure if it is working and just want to test it. At my unit I have a 3phase consumer unit but no 3 phase power socket only 230v sockets. Because times are hard and I want to save money or die trying which most of you will agree will happen if I attempt this my self. I have attached a diagram of how I think it might be done just wanted the professionals opinion.

Thanks

I am an artist and have a picture framing machine that is 3phase, bought it years ago and not sure if it is working and just want to test it. At my unit I have a 3phase consumer unit but no 3 phase power socket only 230v sockets. Because times are hard and I want to save money or die trying which most of you will agree will happen if I attempt this my self. I have attached a diagram of how I think it might be done just wanted the professionals opinion.

Thanks