S

spark 68

Spark what you say is exactly what I want.

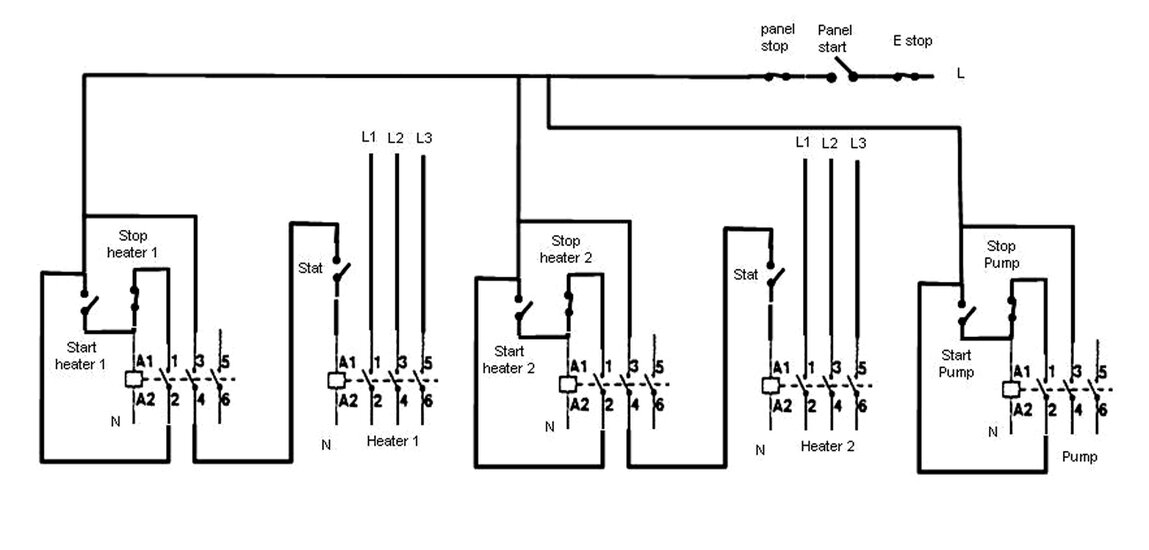

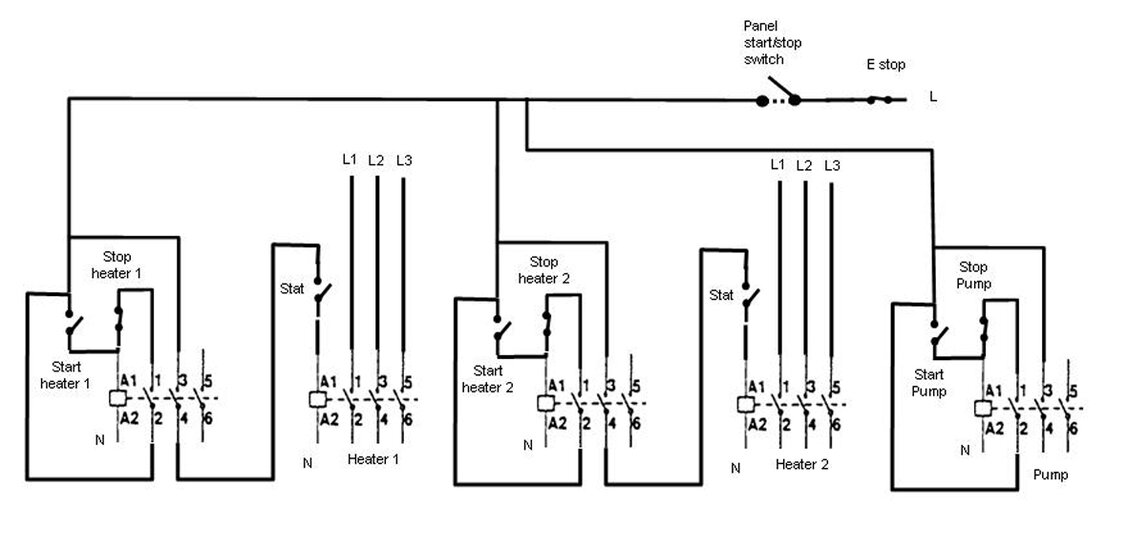

What I did on the paper above is what I think your drawing is telling me to do.

My drawing will be replicated for the 2nd heater as per your post, except for emergency stop which kills all three (2 pumps and heater)

What I'm asking is what's wrong with how I've drawn it out?

All of the contactor/relay contacts on my drawing are normally open (N/O)

arty: OP seems happy with it but he'll rarely come across such a layout in the real world....well maybe on the wiring bumf with a start stop contactor manufacturers connection plan and cheers JP for the challenge of doing a 1day wonder course on on the teachings of schematics

arty: OP seems happy with it but he'll rarely come across such a layout in the real world....well maybe on the wiring bumf with a start stop contactor manufacturers connection plan and cheers JP for the challenge of doing a 1day wonder course on on the teachings of schematics