J

jparker86

Hello,

I am new to the forum and would be most grateful if anyone here could help me with a project I am working on.

I have a control panel which I have made that controls 2 x heaters and 1 x pump.

Both heaters are 6kW (three phase) and the pump is single phase.

It all works, and I have on/off push buttons to operate the heaters and pump all run via the emergency stop button.

Where I am stuck is that my three phase heaters have a built in thermostat, which switches the contactor from on to off when the heat exceeds x degrees. My problem is that with my current design, unless someone presses the start button again it wont switch back on!

Under my current design, the thermostat isn't installed I left this until last (I underestimated how easy it would be).

Currently, all that happens is the device will turn on and off.

What I want is for the thermostat to cut in and cut off the power to the heater when temperature gets too high.

In my head I am thinking the best idea would be to have a contactor which is controlled via the on/off buttons, and that powers another contactor that is controlled by the thermostat?... or am I missing something that could help me?

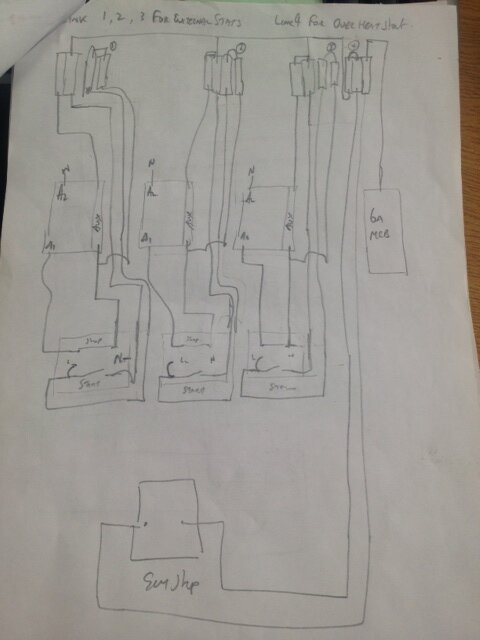

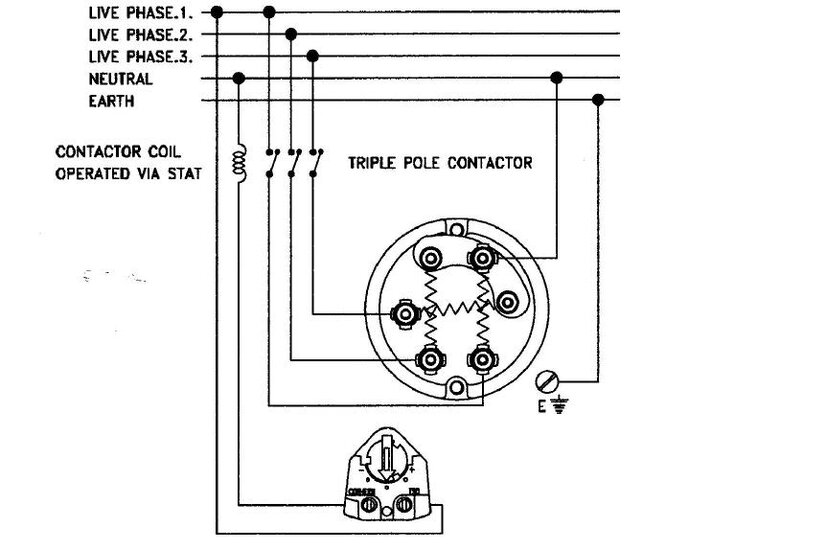

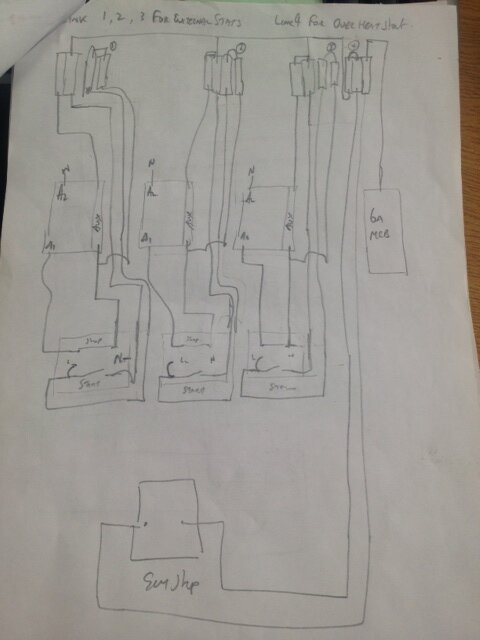

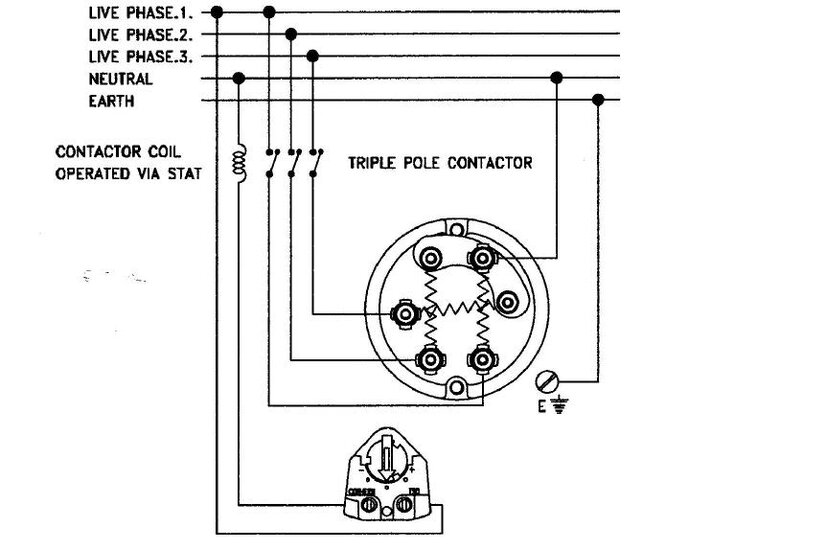

I below attach the wiring diagram for both the heater in question and the control circuit diagram.

Any help would be gratefuly rec'd.

I am new to the forum and would be most grateful if anyone here could help me with a project I am working on.

I have a control panel which I have made that controls 2 x heaters and 1 x pump.

Both heaters are 6kW (three phase) and the pump is single phase.

It all works, and I have on/off push buttons to operate the heaters and pump all run via the emergency stop button.

Where I am stuck is that my three phase heaters have a built in thermostat, which switches the contactor from on to off when the heat exceeds x degrees. My problem is that with my current design, unless someone presses the start button again it wont switch back on!

Under my current design, the thermostat isn't installed I left this until last (I underestimated how easy it would be).

Currently, all that happens is the device will turn on and off.

What I want is for the thermostat to cut in and cut off the power to the heater when temperature gets too high.

In my head I am thinking the best idea would be to have a contactor which is controlled via the on/off buttons, and that powers another contactor that is controlled by the thermostat?... or am I missing something that could help me?

I below attach the wiring diagram for both the heater in question and the control circuit diagram.

Any help would be gratefuly rec'd.