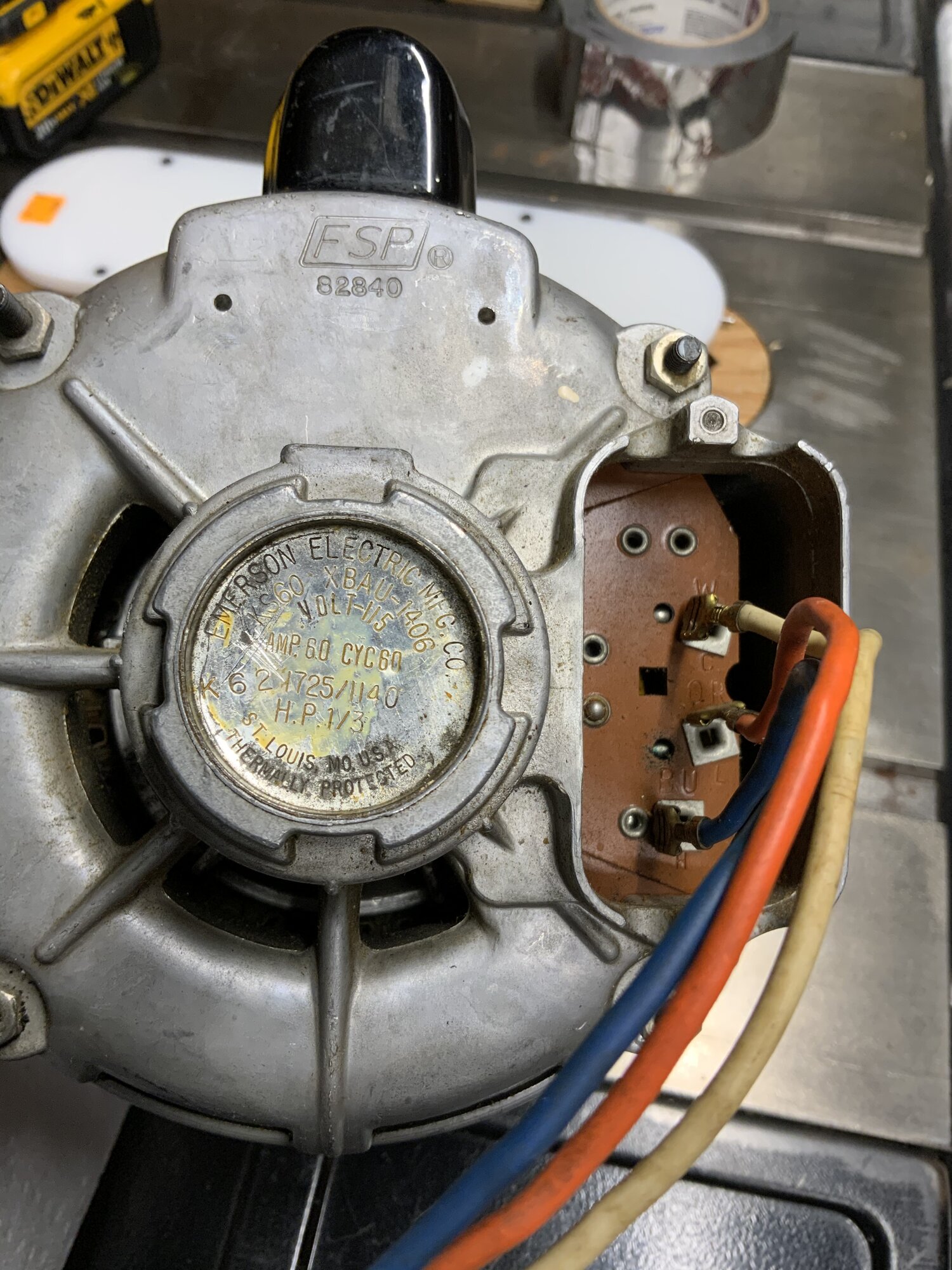

I picked up a 7.5W 110V TEFC single-phase induction motor for super cheap. I may use it on a home made lathe or stationary-sander for my woodshop.

It's not running. I read that the run windings would probably have less impedance than the start windings. I was only able to get and measure conductivity, ~4.5 ohms, between one pair made from the 3 wires extant (checked them at the motor terminals.) I opened the run-capacitor cover and shorted it across its pair of terminals - no spark. Should it have sparked if it was a good cap?

The capacitor also appeared to have a bit of a leak at the top, (picture).

Since a new one that offers the same spec's was US$6.50 shipped, I ordered the replacement. Does it look like this cap was probably bad based on that appearance? Since it's alternating current, polarity won't matter on the re-installation, right?

Since a new one that offers the same spec's was US$6.50 shipped, I ordered the replacement. Does it look like this cap was probably bad based on that appearance? Since it's alternating current, polarity won't matter on the re-installation, right?

The cap's side view and spec's. The new one has same mfd (161-193) value range and 120v specified, but close enough, right?

Last, in wiring it up, I'll have 120V with hot + neutral + ground. Which wire goes where? Should the be another part such as a 'potential relay' to operate this motor?

It's not running. I read that the run windings would probably have less impedance than the start windings. I was only able to get and measure conductivity, ~4.5 ohms, between one pair made from the 3 wires extant (checked them at the motor terminals.) I opened the run-capacitor cover and shorted it across its pair of terminals - no spark. Should it have sparked if it was a good cap?

The capacitor also appeared to have a bit of a leak at the top, (picture).

The cap's side view and spec's. The new one has same mfd (161-193) value range and 120v specified, but close enough, right?

Last, in wiring it up, I'll have 120V with hot + neutral + ground. Which wire goes where? Should the be another part such as a 'potential relay' to operate this motor?