- Sep 13, 2010

- 2,405

- 2,300

- 355,788

- If you're a qualified, trainee, or retired electrician - Which country is it that your work will be / is / was aimed at?

- United Kingdom

- What type of forum member are you?

- Electrical Engineer (Qualified)

Hi guys, struggling with a problem wondered if anyone can help.

Had 2 A/C units failed on me, spare parts not available til end of August... :-(

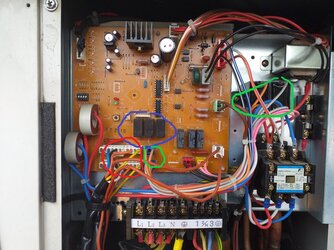

The faults were caused by the fan units which vapourised tracks on the PCB, great design , not.

I can repair the PCBs but the fans are dual fans that come on at the same time so i am hoping that only one fan has failed and that i can at least get one fan assembly working out of the 2 assemblies i have. I .e. i have 4 fans but need 2 to get going again, so i am trying to test the 4 fans and get 2 good ones

This is what i have done so far.

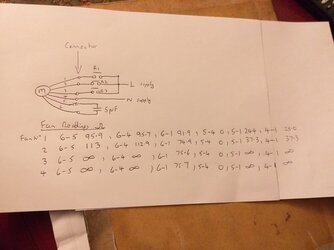

1. Caps are 5uF just one per fan, all tested OK

2. IR all good

3. Continuity giving different readings across fans but quite frankly cannot work out from that which ones are good or bad.

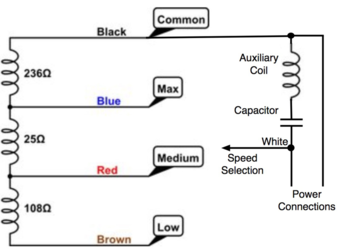

I believe these fans are dual speed. i.e. high and low.

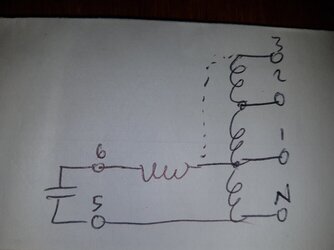

There are 6 wires coming out of the motor:

2 go to the cap as its external - no problem.

1 is Neutral, again no problem i can trace the tracks on the PCB

Then i have 3 wires left.

All three wires go to 3 relays which switch 240V to the motor, i do not know how the relays are switched but they are all wired in parallel so if a relay is energised it puts 240V onto the relevant wire to the motor

What has got me baffled is why do i have a choice of 3 for a 2 speed motor.

Appreciate any help in working out how the windings are configured

Had 2 A/C units failed on me, spare parts not available til end of August... :-(

The faults were caused by the fan units which vapourised tracks on the PCB, great design , not.

I can repair the PCBs but the fans are dual fans that come on at the same time so i am hoping that only one fan has failed and that i can at least get one fan assembly working out of the 2 assemblies i have. I .e. i have 4 fans but need 2 to get going again, so i am trying to test the 4 fans and get 2 good ones

This is what i have done so far.

1. Caps are 5uF just one per fan, all tested OK

2. IR all good

3. Continuity giving different readings across fans but quite frankly cannot work out from that which ones are good or bad.

I believe these fans are dual speed. i.e. high and low.

There are 6 wires coming out of the motor:

2 go to the cap as its external - no problem.

1 is Neutral, again no problem i can trace the tracks on the PCB

Then i have 3 wires left.

All three wires go to 3 relays which switch 240V to the motor, i do not know how the relays are switched but they are all wired in parallel so if a relay is energised it puts 240V onto the relevant wire to the motor

What has got me baffled is why do i have a choice of 3 for a 2 speed motor.

Appreciate any help in working out how the windings are configured