- Reaction score

- 0

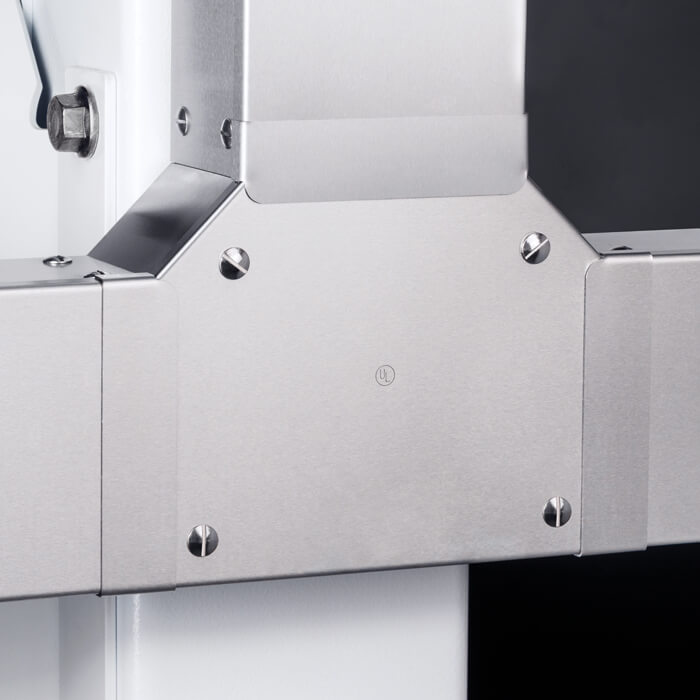

Doing some work in a commercial restaurant/kitchen the builders had already boarded and plastered the walls meaning my only viable route is to use trunking high level to get cables to the points in need do I need to use metal conduit or trunking or can plastic be used some trunking will be in the seating area and toilet not much of it will actually be in the main kitchen area itself

Also the floor has be tiled and the client wants some appliances in the middle of the kitchen can I run some kind of trunking on the floor and use metal sockets under the appliances

Also the floor has be tiled and the client wants some appliances in the middle of the kitchen can I run some kind of trunking on the floor and use metal sockets under the appliances