C

Capn Ahab

Not sure if this is the right place to post this. Please advise if not.

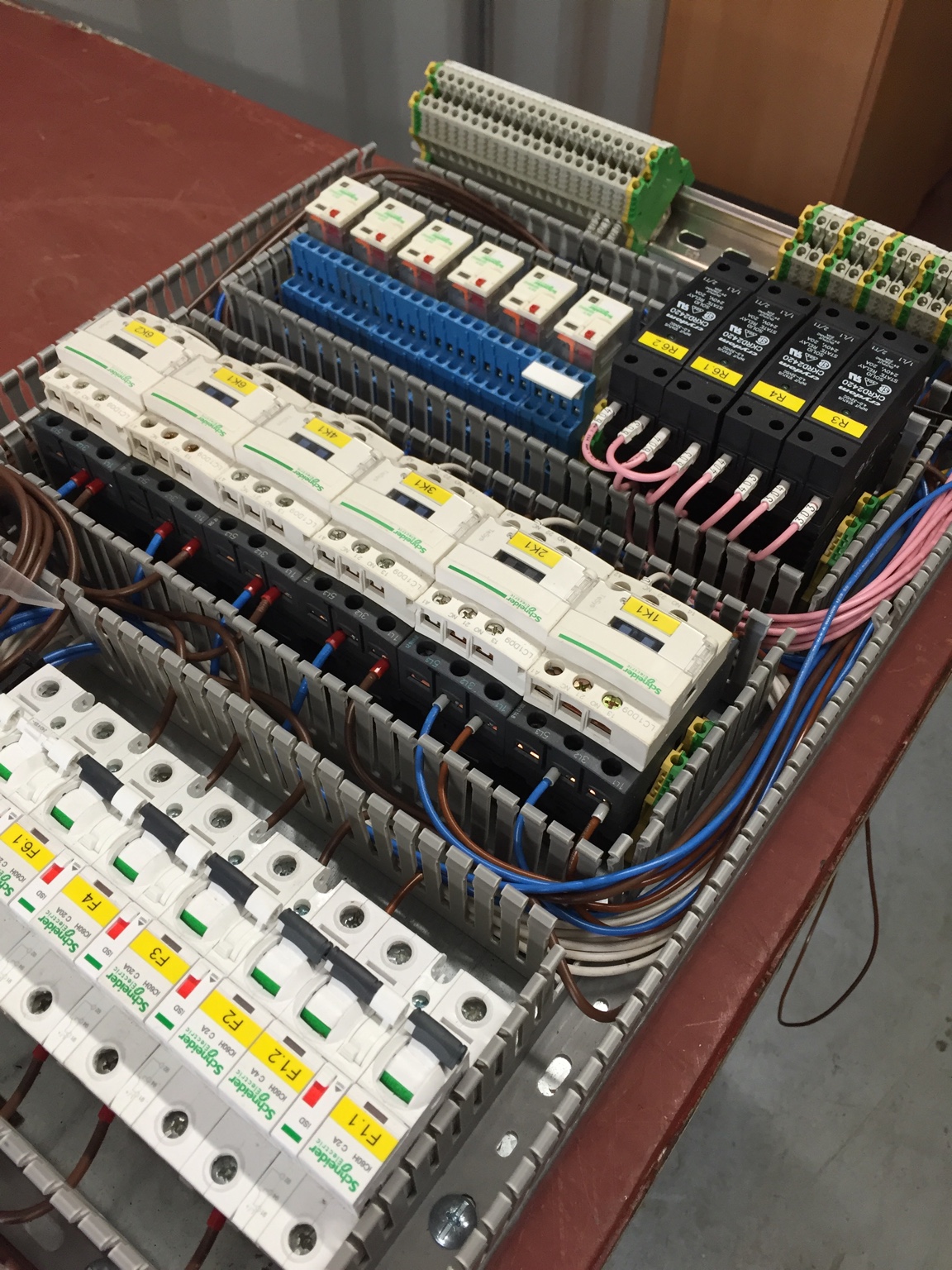

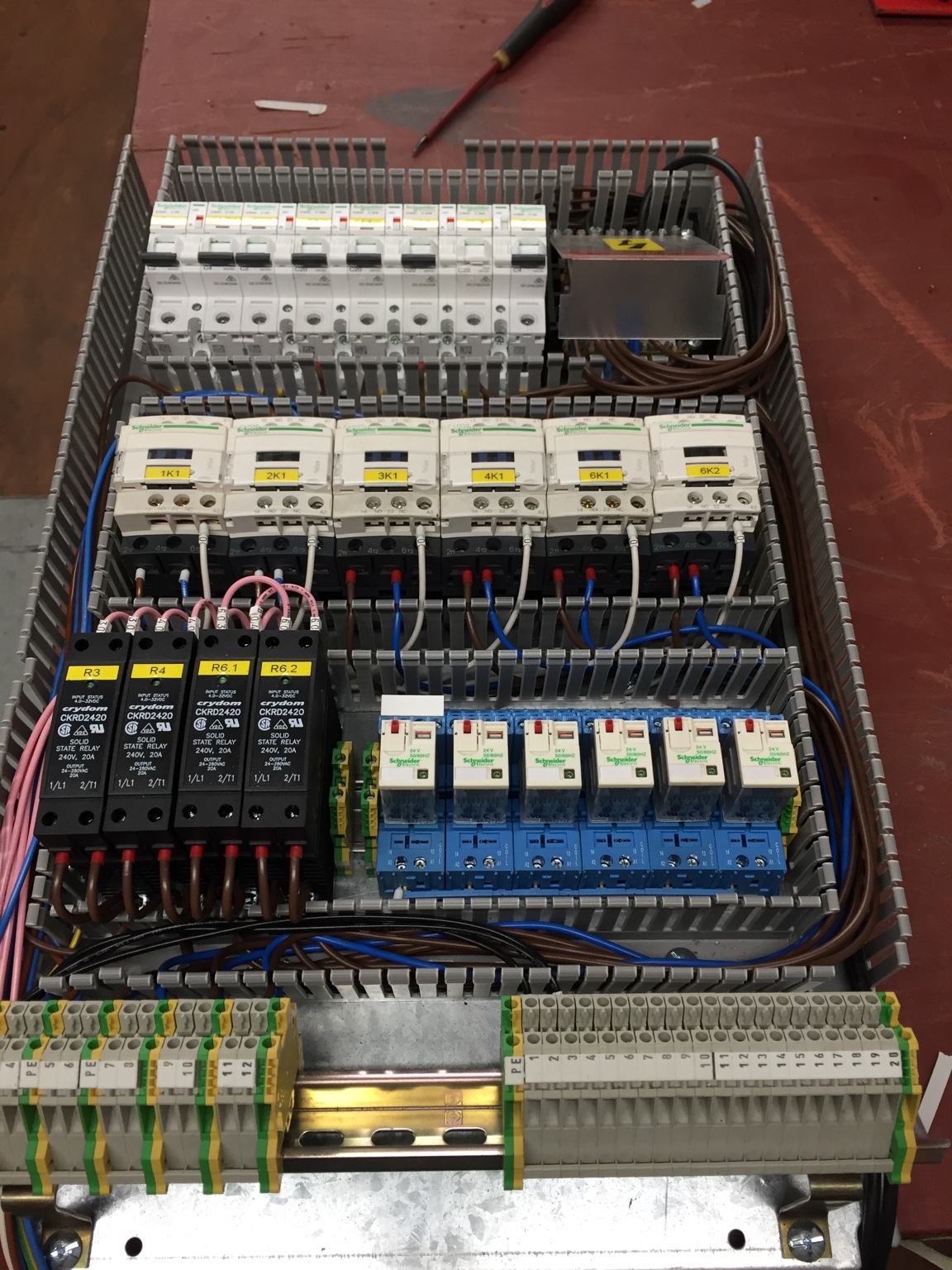

A client I have done some work for runs a brewery supply company, mainly dealing in vessels, pumps etc, and has asked me to build a control panel to run elements and pumps off PIDs and SSRs as he has a customer that needs one. It might just be a one-off or there might be demand for more.

I have looked at gov.uk guidance about manufacturing electrical equipment and aside from the obvious needs to have an earthed enclosure etc, everything seems geared towards having a CE mark to demonstrate compliance with current safety standards.

My question is, do I need to go for the whole shebang and do a technical document + declaration of conformity + CE marking for a one off piece of equipment? Especially since, most, if not all of the components will already be CE marked and the panel will be a fixed unit with a permanent supply?

My client seems to think a PAT test would be sufficient, but I'm not sure...

Additionally, how does the CE marking requirement apply to refurbished or reclaimed light fittings?

I think if I was doing the install as well the question would be moot, as the CE marking on each individual component + the installation certificate would suffice, but it's essentially an off the shelf piece of kit that I've been asked for.

If anyone can point me in the direction of the right people to ask these questions I'd be most grateful!

Thanks

A client I have done some work for runs a brewery supply company, mainly dealing in vessels, pumps etc, and has asked me to build a control panel to run elements and pumps off PIDs and SSRs as he has a customer that needs one. It might just be a one-off or there might be demand for more.

I have looked at gov.uk guidance about manufacturing electrical equipment and aside from the obvious needs to have an earthed enclosure etc, everything seems geared towards having a CE mark to demonstrate compliance with current safety standards.

My question is, do I need to go for the whole shebang and do a technical document + declaration of conformity + CE marking for a one off piece of equipment? Especially since, most, if not all of the components will already be CE marked and the panel will be a fixed unit with a permanent supply?

My client seems to think a PAT test would be sufficient, but I'm not sure...

Additionally, how does the CE marking requirement apply to refurbished or reclaimed light fittings?

I think if I was doing the install as well the question would be moot, as the CE marking on each individual component + the installation certificate would suffice, but it's essentially an off the shelf piece of kit that I've been asked for.

If anyone can point me in the direction of the right people to ask these questions I'd be most grateful!

Thanks