I'm replacing a threaded lamp holder and the original wires had ferrules on the end so I'm replicating this as it seems like it ensures a more reliable grip between the contacts.

Given that the entry point for the contacts will create a 90 degree bend in the wires, I think that the kink will be a weak point which, over time, could cause the wire to break off, which is what appears to have happened previously.

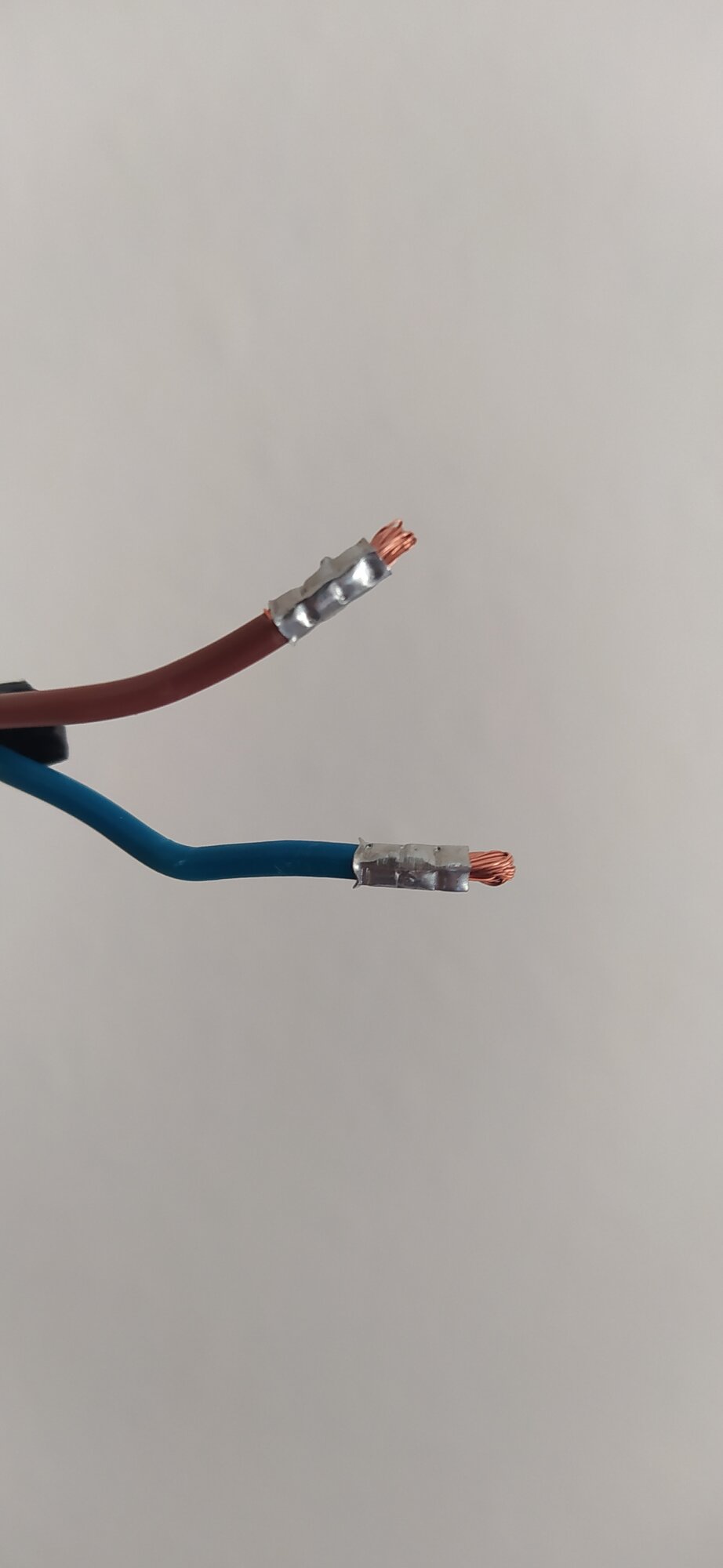

My 'solution' is to apply the ferrule partly over wire sheath itself to minimise the risk of the wire breaking.

Does this approach seem sensible, or am i being an idiot?

Given that the entry point for the contacts will create a 90 degree bend in the wires, I think that the kink will be a weak point which, over time, could cause the wire to break off, which is what appears to have happened previously.

My 'solution' is to apply the ferrule partly over wire sheath itself to minimise the risk of the wire breaking.

Does this approach seem sensible, or am i being an idiot?

Last edited by a moderator: