Hello people. My old man has a table saw and water has got in the switch, he decided to remove it ready for me to replace and due to poor memory can't remember how it was wired up.

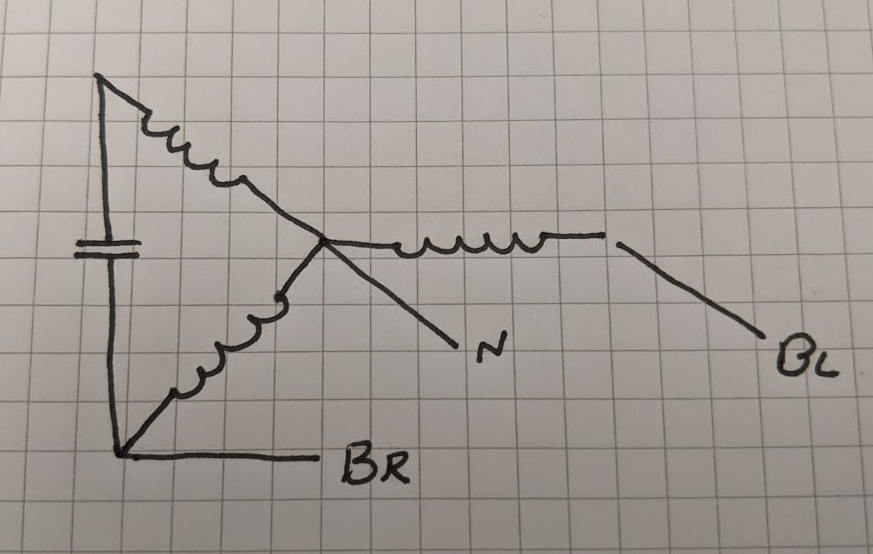

I've not had much experience with motors etc but from what I can work out it's wired as follows:

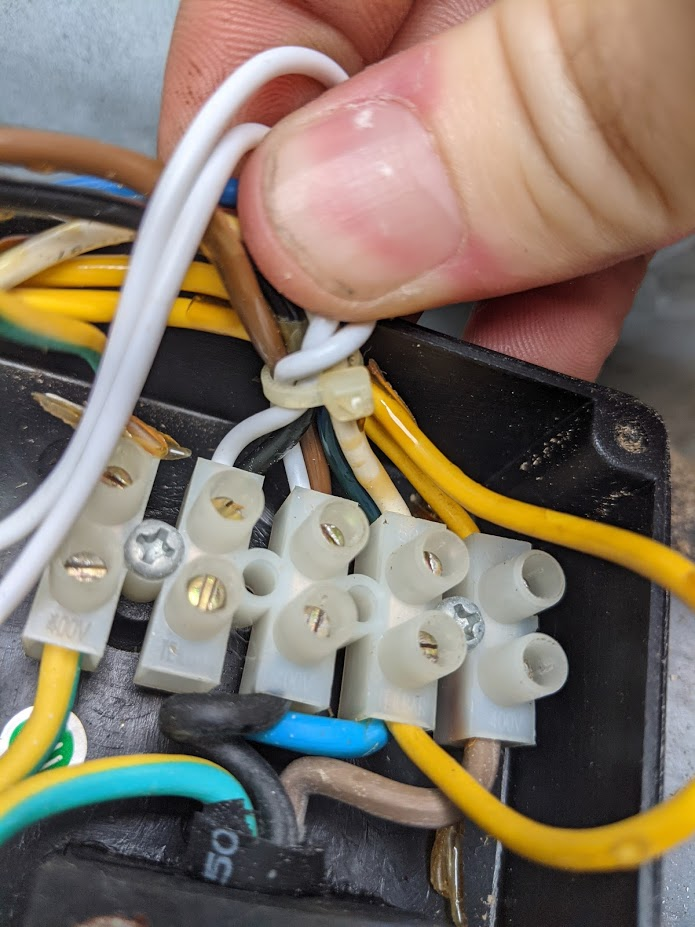

I haven't checked the windings but these are the connections - the nice bright white cables are the capacitor:

I've got a new NVR switch so I assume it's N = 0v and BR & BL = 230v?

From what I see online it's an unusual setup as most single phase motors only have two windings with a capacitor shifting the phase for the second winding.

Cheers!

I've not had much experience with motors etc but from what I can work out it's wired as follows:

I haven't checked the windings but these are the connections - the nice bright white cables are the capacitor:

I've got a new NVR switch so I assume it's N = 0v and BR & BL = 230v?

From what I see online it's an unusual setup as most single phase motors only have two windings with a capacitor shifting the phase for the second winding.

Cheers!