We've done a lot of transformerless inverters and I tend to bond to across the rails ie if there is four rails for a portrait system these have all been TT ,and the array earthed to a rod

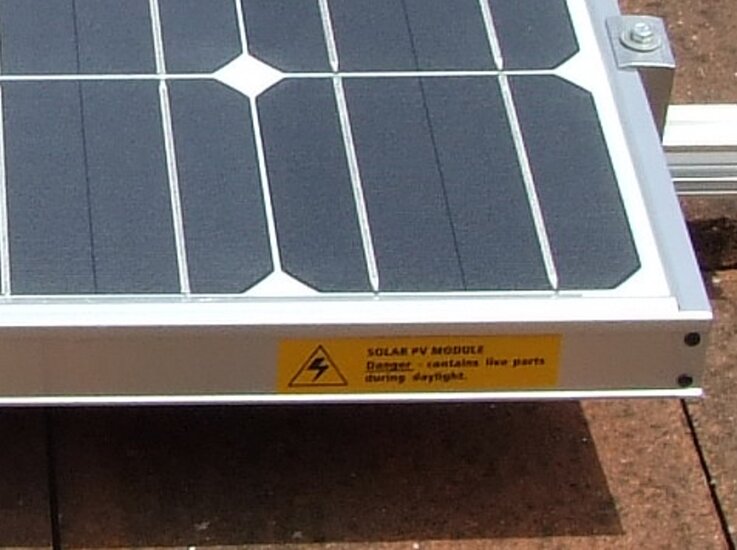

as i posted on another thread i have tested for voltage on the Tl jobs we've done and there is always a voltage of >50v (highest being 108v) on the frame turn the inverter off and it vanishes ,i tell our customers to turn the system off when cleaning panels or working near the array

I did have a pdf explaining this which was possibly from Sma so i'll have a look for it

as i posted on another thread i have tested for voltage on the Tl jobs we've done and there is always a voltage of >50v (highest being 108v) on the frame turn the inverter off and it vanishes ,i tell our customers to turn the system off when cleaning panels or working near the array

I did have a pdf explaining this which was possibly from Sma so i'll have a look for it

Last edited:

)

)