L

lugluglug

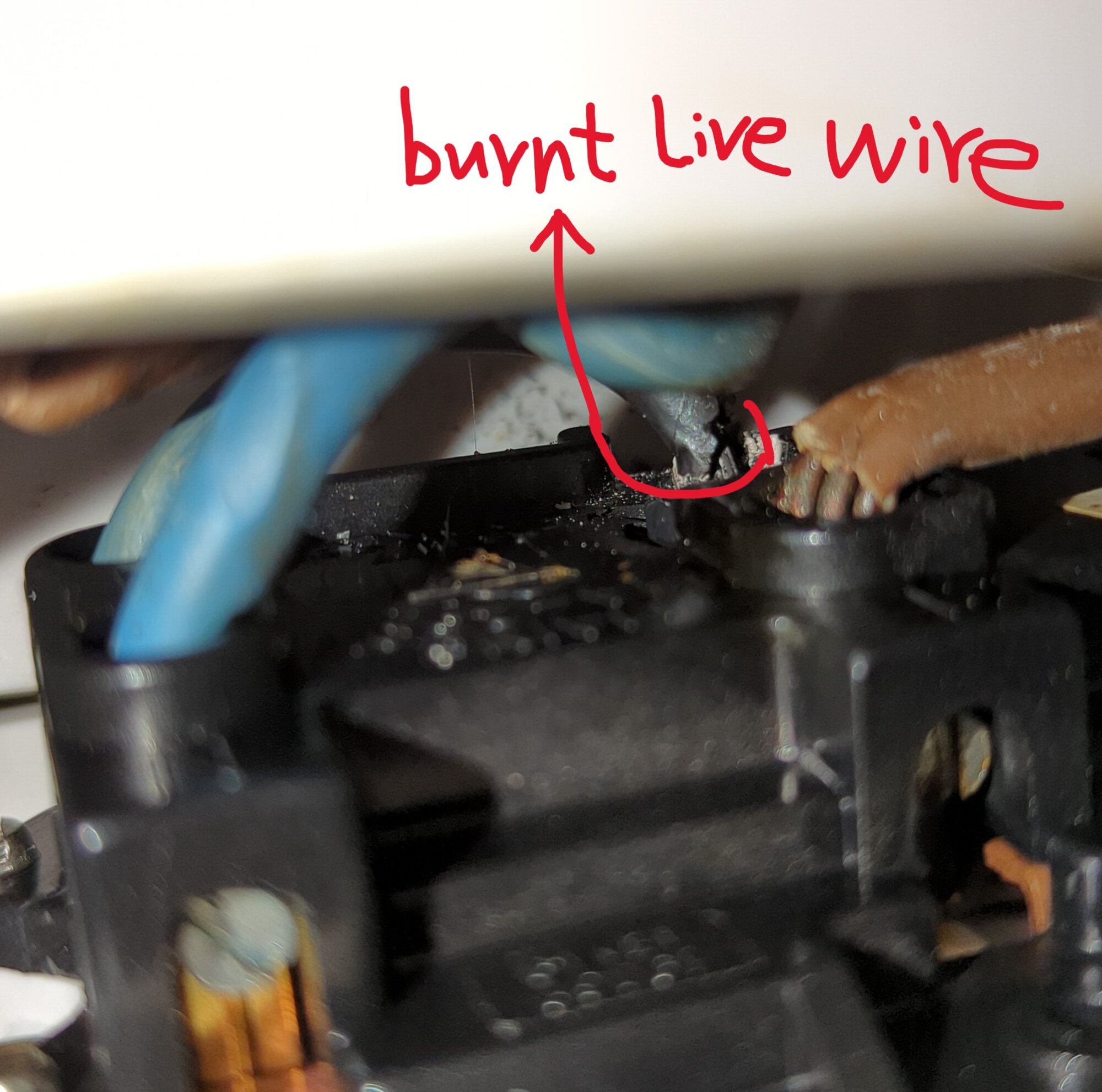

9kw deep fryer, a cooker switch, stop working every few months,

I found the fryer use thin flex cable (see picture 3), it was burnt, the power supply cable are much thicker and it has no problem.

The fryer thin flex cable was just plugged into the switch, no lug,

Am I right? I guess it can be the thin copper flex cable are not contacted properly with the switch, that's why it overheated,

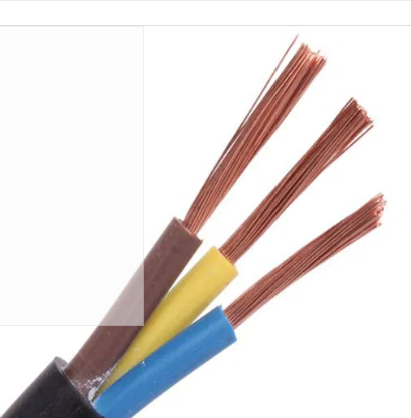

If I soldering the thin flex cable or use a lug ( see pic), it can improved?

Many thanks

I found the fryer use thin flex cable (see picture 3), it was burnt, the power supply cable are much thicker and it has no problem.

The fryer thin flex cable was just plugged into the switch, no lug,

Am I right? I guess it can be the thin copper flex cable are not contacted properly with the switch, that's why it overheated,

If I soldering the thin flex cable or use a lug ( see pic), it can improved?

Many thanks