M

Mr Malcontent

Hello all, visit to site today to see in an install of a 315A 400V supply to a machine. Client mentioned previously they were going to use single core AWA cables from the distribution board to the machine so I advised them amongst other things to factor reg 525.1 and how they terminate the individual conductors into any ferrous enclosures.

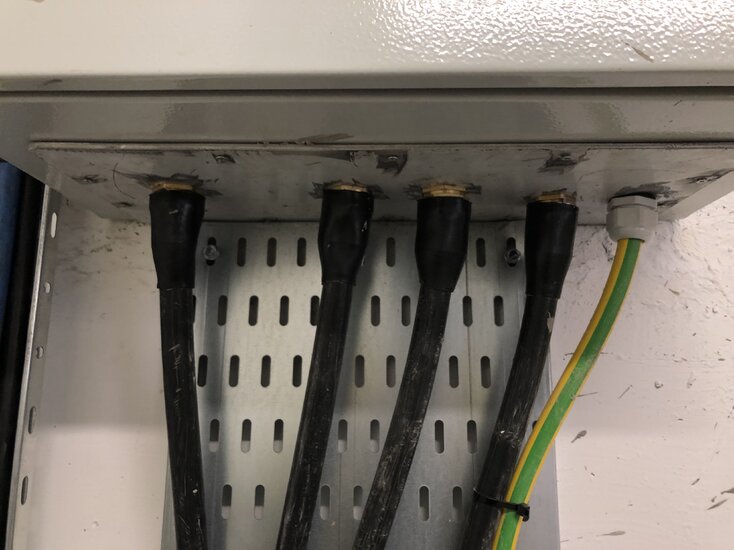

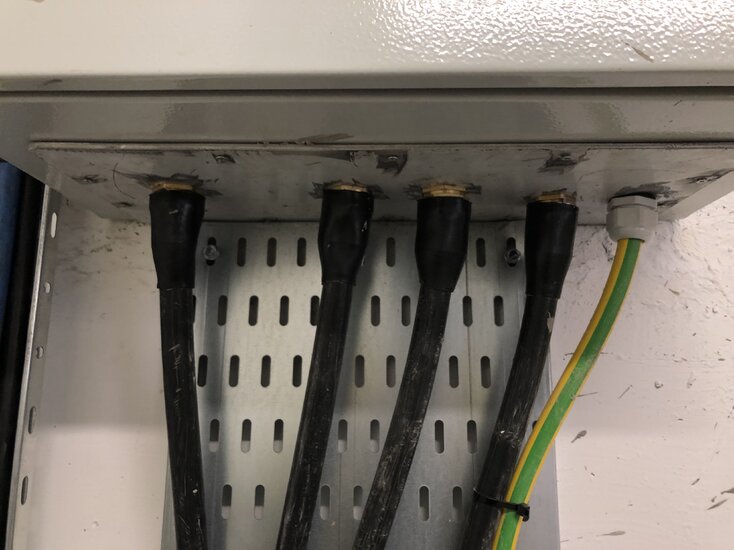

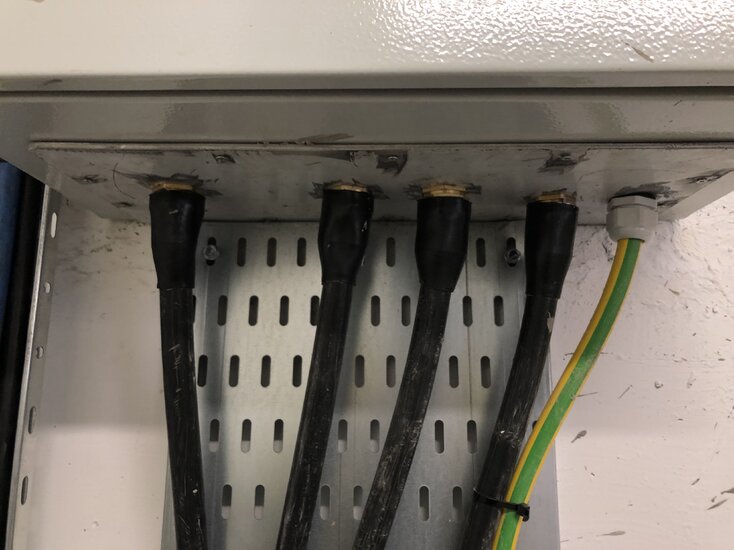

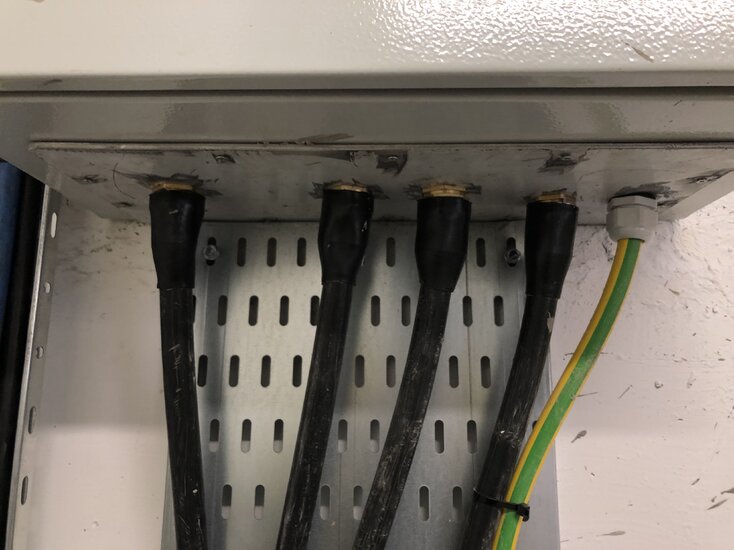

So, turned up today to find a separate 4 pole 947-3 isolator installed in a steel enclosure separate to the machine, conductors installed as per photos. The gland plate has been replaced with what looks to be a stainless steel plate and the outgoing conductors terminated directly onto the top horizontal section of the steel enclosure through compression glands! The outgoing conductors are then installed to a length of cable tray along the wall and into the base of the control panel through a slotted gland plate.

I am lost for words?

So, turned up today to find a separate 4 pole 947-3 isolator installed in a steel enclosure separate to the machine, conductors installed as per photos. The gland plate has been replaced with what looks to be a stainless steel plate and the outgoing conductors terminated directly onto the top horizontal section of the steel enclosure through compression glands! The outgoing conductors are then installed to a length of cable tray along the wall and into the base of the control panel through a slotted gland plate.

I am lost for words?