D

davesparks

I've been working my way through some EICR remedials in a theatre and one of them is to sort out a slightly high Zs on a submain.

Thankfully whoever installed it put the banjo on the gland and even put a bolt through it, they just didn't add a flylead, so its going to be relatively easy to fix that element of it. But it has got me wondering what could be done, or what other people might do if there wasn't already a banjo on the gland.

Obviously with most such situations you'd probably disconnect the conductors, remove the locknut and replace it with an earthing nut. But in this instance the cable is 400mm 4 core (I assume whoever designed this had never actually been on site and had to install a cable of that size or else they'd have split it into parallel cables, or they just hated the poor guys who had to install it) so there's not much chance of that happening.

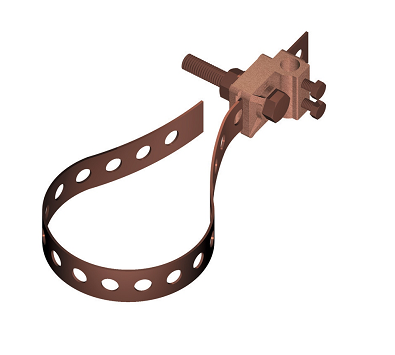

I think if there hadn't been a banjo I would probably would have gone with something like a big earth clamp like you'd use for attaching lightning conductors to pipework and attached it to the main body of the gland. Something like this:

And this is the offending gland:

Thankfully whoever installed it put the banjo on the gland and even put a bolt through it, they just didn't add a flylead, so its going to be relatively easy to fix that element of it. But it has got me wondering what could be done, or what other people might do if there wasn't already a banjo on the gland.

Obviously with most such situations you'd probably disconnect the conductors, remove the locknut and replace it with an earthing nut. But in this instance the cable is 400mm 4 core (I assume whoever designed this had never actually been on site and had to install a cable of that size or else they'd have split it into parallel cables, or they just hated the poor guys who had to install it) so there's not much chance of that happening.

I think if there hadn't been a banjo I would probably would have gone with something like a big earth clamp like you'd use for attaching lightning conductors to pipework and attached it to the main body of the gland. Something like this:

And this is the offending gland: