R

radiohead

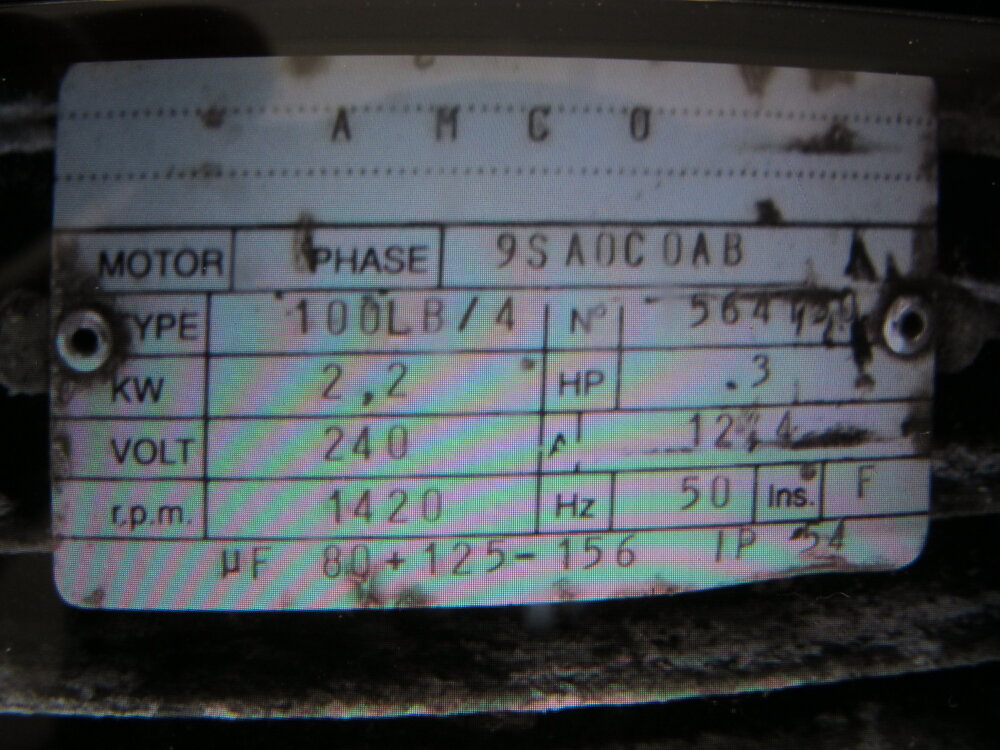

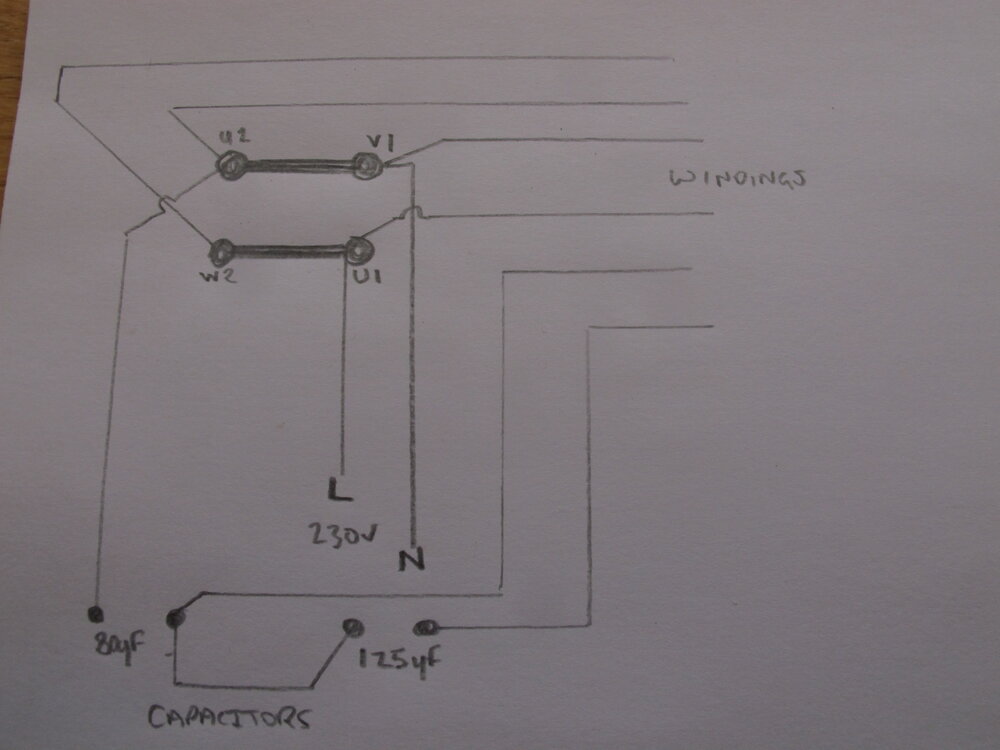

I'd really appreciate some help with a single phase motor driving a mixing machine. Firstly let me state now I have little experience of motors but am trying to help out a client. The mixer mechanics were fully serviced by others with new bearings and runs smoothly. Before being serviced the 125 mf cap had burnt out, and after the service I was asked to replace the cap like for like to get it running. It burnt out again. A second new cap is clearly going the same way.

Question is are the caps wired correctly,(it's an old motor and has clearly been messed with) and if so what other reason might be the cause?

I have included a pic of the motor plate and a diagram of how the 80 and 125mf caps are currently connected.

Thanks in advance for any assistance.

Question is are the caps wired correctly,(it's an old motor and has clearly been messed with) and if so what other reason might be the cause?

I have included a pic of the motor plate and a diagram of how the 80 and 125mf caps are currently connected.

Thanks in advance for any assistance.