_q12x_

DIY

- Reaction score

- 212

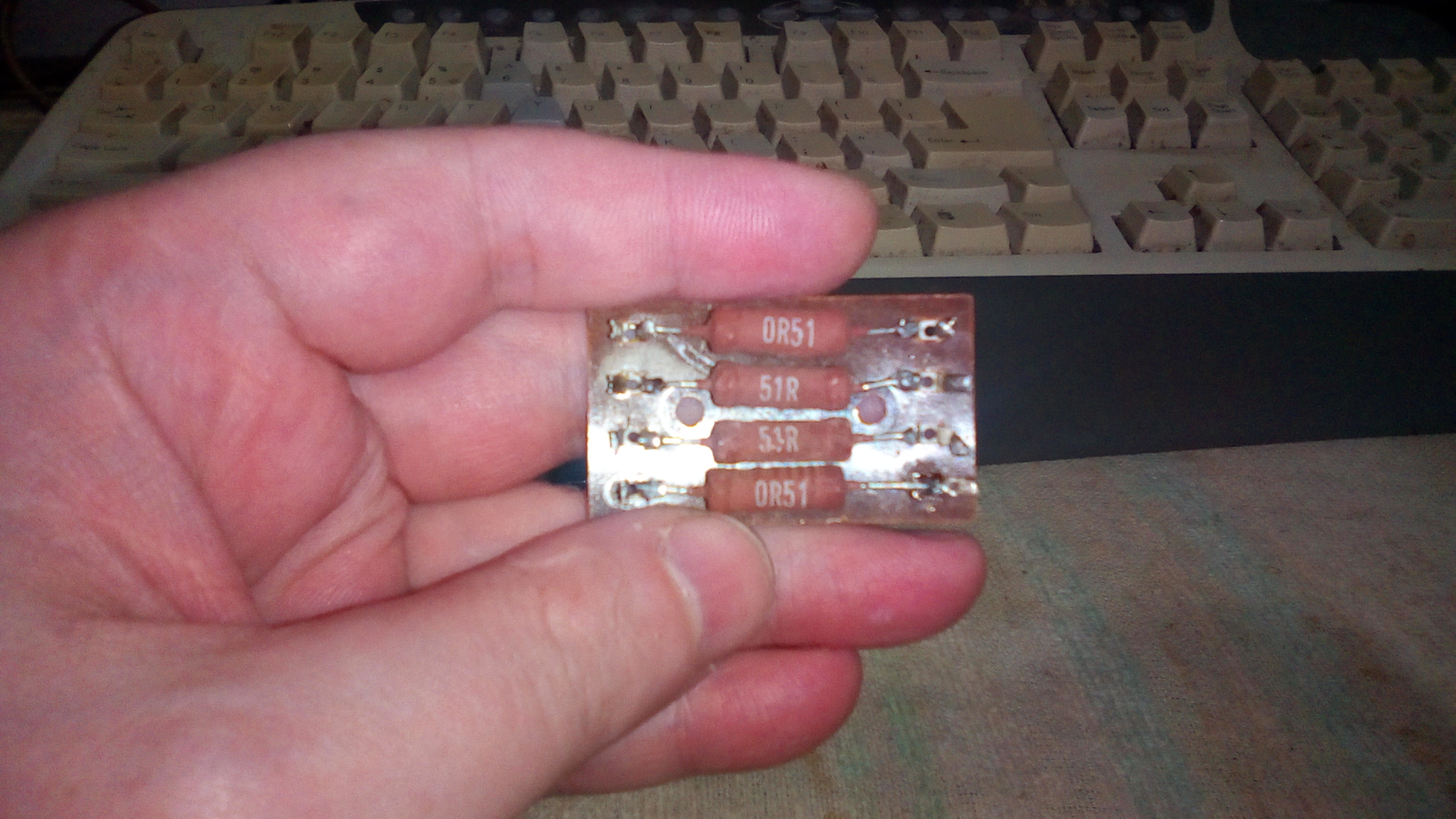

- I want to know what these -unknown- resistors Wattage are !?

First of all, they are scrapped. Then, we really dont know in what part of the circuit they had sit, in the gate of the circuit where high power was entering? or in the core of the circuit, where the power didnt matter that much, like a logic circuit for example. We also dont know how much stress they took, they may be brand "new" but --old-- stock, or they took some hard unforgiving heat? Also how much time they got electrical exposure, minutes? days? months? years? That will tire the component as well. Also, what technology was used in building them, using high Wattage resistance or small resistance to wattage? We dont know all of these things.

And this question is more universal than to these ones I have in my hand. I also have a few other candidates, very strange in shape, also regional origins (some made in Romania, some in URSS, some in Poland, even CHINA!!! haha).

I also highly suspect the technology used in the past, like 70's,80's,90's,2000's, differed greatly from today's. For a 1/4W or 1/8W was used a BIG or LONG resistor case, while compared to today SMD's, the same wattage is literally on a tip of a needle.

First of all, they are scrapped. Then, we really dont know in what part of the circuit they had sit, in the gate of the circuit where high power was entering? or in the core of the circuit, where the power didnt matter that much, like a logic circuit for example. We also dont know how much stress they took, they may be brand "new" but --old-- stock, or they took some hard unforgiving heat? Also how much time they got electrical exposure, minutes? days? months? years? That will tire the component as well. Also, what technology was used in building them, using high Wattage resistance or small resistance to wattage? We dont know all of these things.

And this question is more universal than to these ones I have in my hand. I also have a few other candidates, very strange in shape, also regional origins (some made in Romania, some in URSS, some in Poland, even CHINA!!! haha).

I also highly suspect the technology used in the past, like 70's,80's,90's,2000's, differed greatly from today's. For a 1/4W or 1/8W was used a BIG or LONG resistor case, while compared to today SMD's, the same wattage is literally on a tip of a needle.

- I want to test and to --KNOW-- what's the wattage they can run safely !

- How are you doing it, personally? What is the proper technique? What you recommend? I mean to built, not to buy. This should be a fun little mini-project.