- Dec 23, 2023

- 40

- 2

- 83

- If you're a qualified, trainee, or retired electrician - Which country is it that your work will be / is / was aimed at?

- United Kingdom

- What type of forum member are you?

- Manufacturer / Distributor / Supplier / Inventor - etc

- Business Name

- Mandalblit Services

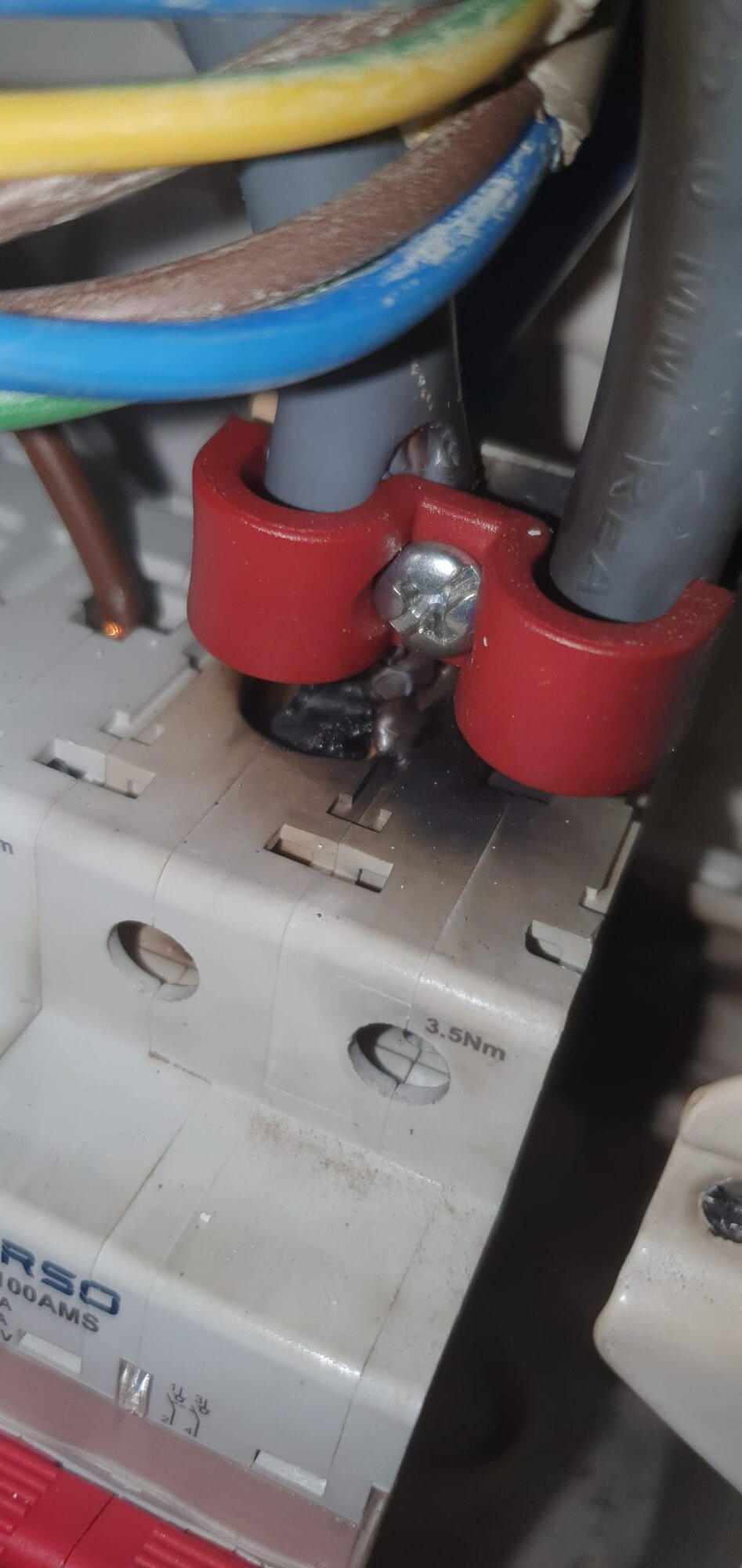

Hi lads 5 year safety inspection the spark put the tails back and later line 2 of the 3 phase blew blowing the box off the wall and taking out the main fuse on the same line into the building can you all just say quickly what you think the spark may have done wrong ?

Cheers

Cheers

Last edited by a moderator: