W

Worcester

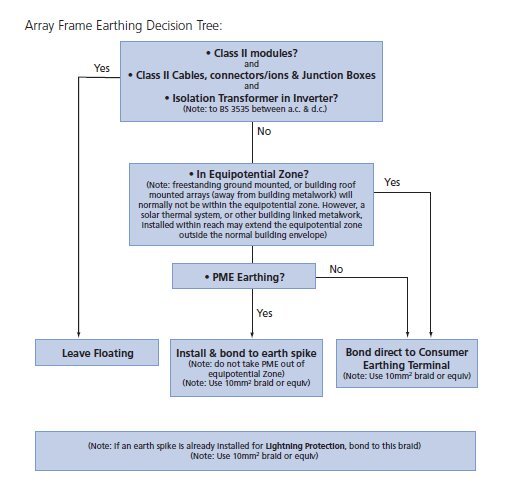

Don't want to get into a discussion here about when to earth the array or not.

Lets' assume it MUST be earthed.

How are people doing it?

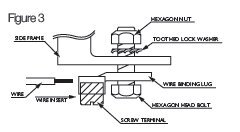

1) Attaching an earth strap (braid or cable?) between each panel and the rail (one or both?), then joining all the rails together (parallel), and then a single earth.

2) Joining the rails together in parallel then a single earth (And making the assumption that the panels mounts will earth the panels to the rails)?

Or:

3) Make the assumption that the panels and panel mounts will join all the rails and panels together and attaching a single earth cable to one rail?

4) Any other way

5) What do you think should be Best Practice?

Thx

Lets' assume it MUST be earthed.

How are people doing it?

1) Attaching an earth strap (braid or cable?) between each panel and the rail (one or both?), then joining all the rails together (parallel), and then a single earth.

2) Joining the rails together in parallel then a single earth (And making the assumption that the panels mounts will earth the panels to the rails)?

Or:

3) Make the assumption that the panels and panel mounts will join all the rails and panels together and attaching a single earth cable to one rail?

4) Any other way

5) What do you think should be Best Practice?

Thx

, how are people doing it , what is best practice ...

, how are people doing it , what is best practice ...