W

wade88

Hi lads,ladies

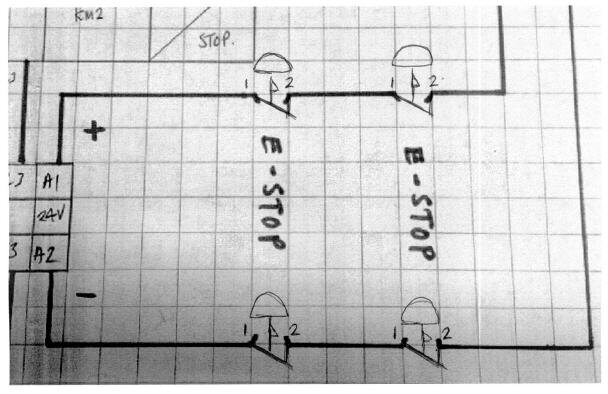

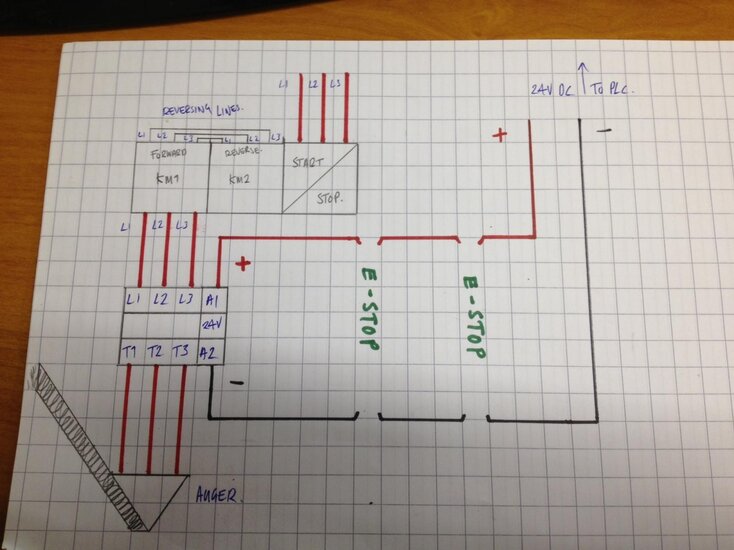

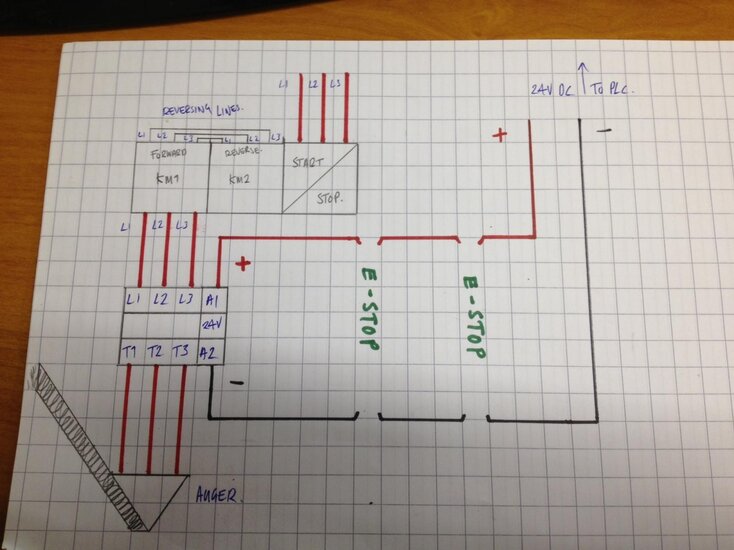

I have just put together an E stop circuit that is integrated into an auger motor control circuit w/ forward/reverse DOL. I have posted this awful diagram on another post but i am having some trouble when i put 24v down the + line and getting a readying of 0V as soon as it hits the first E stop.

I just drew this up really quickly yesterday to give a better idea of what im looking at.

I just drew this up really quickly yesterday to give a better idea of what im looking at.

The 24V signal will actually be supplied by the PLC module, but the PLC chap has yet to come in and finish off his work so i wanted to just test mt circuit prior to his arrival and put 24v down the line. I was getting a voltage until it hit the first E stop which is located on the side of the auger hopper.

I have a 24v DC mini contactor relay in the adaptable box with the E stop circuit coming from the A1 and A2 ports in tri-rated 18AWG cable, the circuit continues round to the second E stop the other side of the hopper and then will carry on to the PLC when its ready. When the PLC calls for product it will send the 24V signal through the line, through the E stops and onto the contactor, energising the coil and closing the circuit. That's the plan

But like i mentioned, even after putting 24V down it, simulating the PLC signal, when it hits the first E stop, i just lose voltage, and get nothing?

This isn't the sort of work i do everyday, and is my first E stop circuit. I posted previously regarding this topic and received from very useful feedback from a lot of guys regarding its design etc, so would really appreciated a little more on this matter.

Am i missing something really obvious, i may have missed a lot out in the description so i apologise if your short on info. Just ask and i shall try and answer you.

Cheers lads, Ben

I have just put together an E stop circuit that is integrated into an auger motor control circuit w/ forward/reverse DOL. I have posted this awful diagram on another post but i am having some trouble when i put 24v down the + line and getting a readying of 0V as soon as it hits the first E stop.

I just drew this up really quickly yesterday to give a better idea of what im looking at.

I just drew this up really quickly yesterday to give a better idea of what im looking at.

The 24V signal will actually be supplied by the PLC module, but the PLC chap has yet to come in and finish off his work so i wanted to just test mt circuit prior to his arrival and put 24v down the line. I was getting a voltage until it hit the first E stop which is located on the side of the auger hopper.

I have a 24v DC mini contactor relay in the adaptable box with the E stop circuit coming from the A1 and A2 ports in tri-rated 18AWG cable, the circuit continues round to the second E stop the other side of the hopper and then will carry on to the PLC when its ready. When the PLC calls for product it will send the 24V signal through the line, through the E stops and onto the contactor, energising the coil and closing the circuit. That's the plan

But like i mentioned, even after putting 24V down it, simulating the PLC signal, when it hits the first E stop, i just lose voltage, and get nothing?

This isn't the sort of work i do everyday, and is my first E stop circuit. I posted previously regarding this topic and received from very useful feedback from a lot of guys regarding its design etc, so would really appreciated a little more on this matter.

Am i missing something really obvious, i may have missed a lot out in the description so i apologise if your short on info. Just ask and i shall try and answer you.

Cheers lads, Ben