W

wade88

Alright lads,

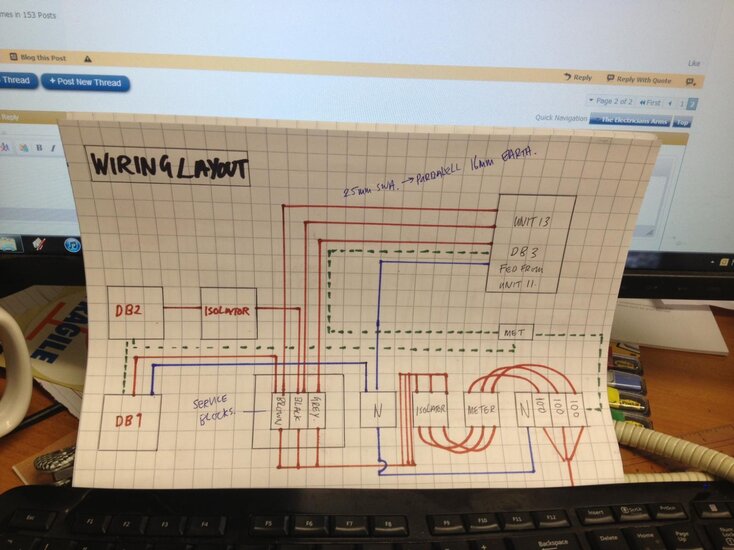

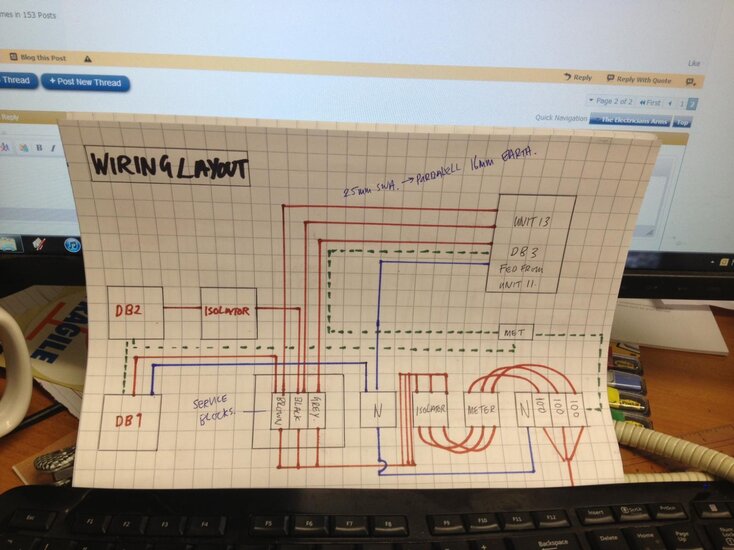

Can anyone see a problem with this. Excuse the drawing, im fairly rubbish at clearly drawing things and have most definitely to all you technical chaps out there, murdered the drawing to bits, but im just trying to get scope around the general idea. Which i think is clear enough.

4 core SWA will be travelling across two warehouses to be terminated into new TP+N board. Planning on taking the existing incoming supply and splitting it down via service blocks to be able to accommodate the existing boards (of minimal load) and the new board. Industrial work such as this is not my usual forte, however it is becoming more of what i do now, i feel competent to do the work, would just appreciate a nudge in the right direction should i need it.

Tin hat is on, if you need to be brutal here, by all means go ahead. i want a safe and future proof install so if i need a good kicking to achieve that then im ready for it. I'll do my very best to answer your questions as accurately as possible.

Cheers guys,

Can anyone see a problem with this. Excuse the drawing, im fairly rubbish at clearly drawing things and have most definitely to all you technical chaps out there, murdered the drawing to bits, but im just trying to get scope around the general idea. Which i think is clear enough.

4 core SWA will be travelling across two warehouses to be terminated into new TP+N board. Planning on taking the existing incoming supply and splitting it down via service blocks to be able to accommodate the existing boards (of minimal load) and the new board. Industrial work such as this is not my usual forte, however it is becoming more of what i do now, i feel competent to do the work, would just appreciate a nudge in the right direction should i need it.

Tin hat is on, if you need to be brutal here, by all means go ahead. i want a safe and future proof install so if i need a good kicking to achieve that then im ready for it. I'll do my very best to answer your questions as accurately as possible.

Cheers guys,

not looking forward to it at all.

not looking forward to it at all.