H

highspark

I've got a job to wire in 6 single phase sockets into a mesh cage room.

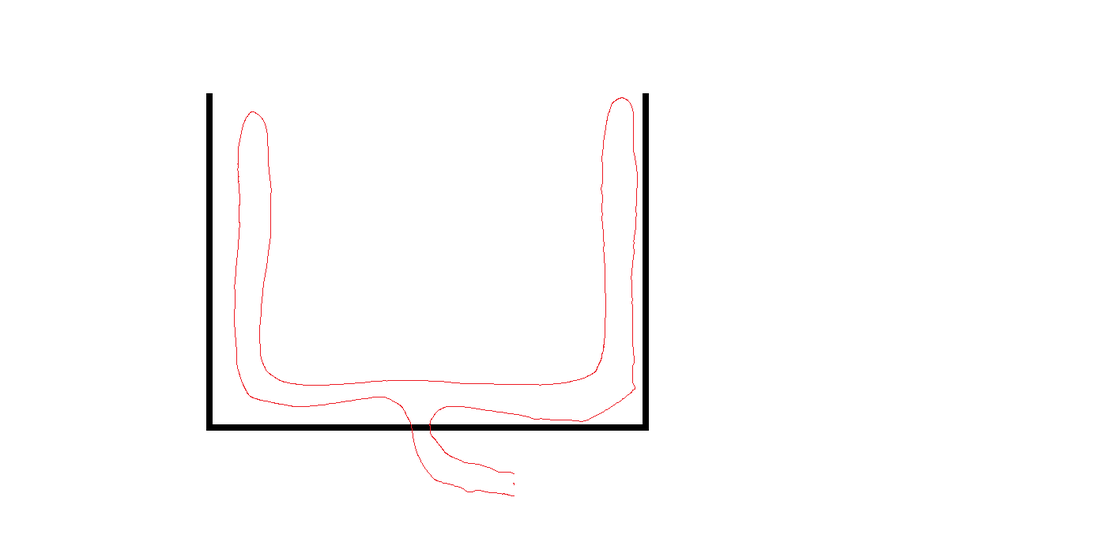

Problem is its not a full square room one section is missing, making it a U shape. it also has no roof.

Considering this instead of running a ring I now want to run two radials contains 3 sockets down either side of the room.

With this being an industrial type workshop I'm not sure whether to go bigger on the radials. What I have been told is it's going to mainly be hand tools and grinders etc.

Would you guys put two simple 2.5mm radials at 20A in or go for a 4mm radial?

Problem is its not a full square room one section is missing, making it a U shape. it also has no roof.

Considering this instead of running a ring I now want to run two radials contains 3 sockets down either side of the room.

With this being an industrial type workshop I'm not sure whether to go bigger on the radials. What I have been told is it's going to mainly be hand tools and grinders etc.

Would you guys put two simple 2.5mm radials at 20A in or go for a 4mm radial?