I'm so glad someone on here is actually able to take a look

Can't wait to see more pictures..

Can't wait to see more pictures..

Sorry, just saw this post and would have offered a free visit to assess. Bloody awful work.

Interested to hear what JK says!

As I said, I figured I'd tag a few of you in but could only remember JK and couldn't search on location, so sorry about that.

Totally agree with SC on this, a total cowboy lash up, hope you haven't paid this bloke yet, although by the tone of post you already have, any certificates issued? was the Herbert who did this registered with any Competent Persons Scheme, NICEIC, NAPIT, ELECSA, STROMA to name a few?

i wouldve polished it as well for that price...

I suspect he may have been polishing something else while he was doing that!

^^^ Part P for Scotland - like thats going to help .................. not

@JK-Electrical .... we need pictures

His spurs?I suspect he may have been polishing something else while he was doing that!

Quality

Quality

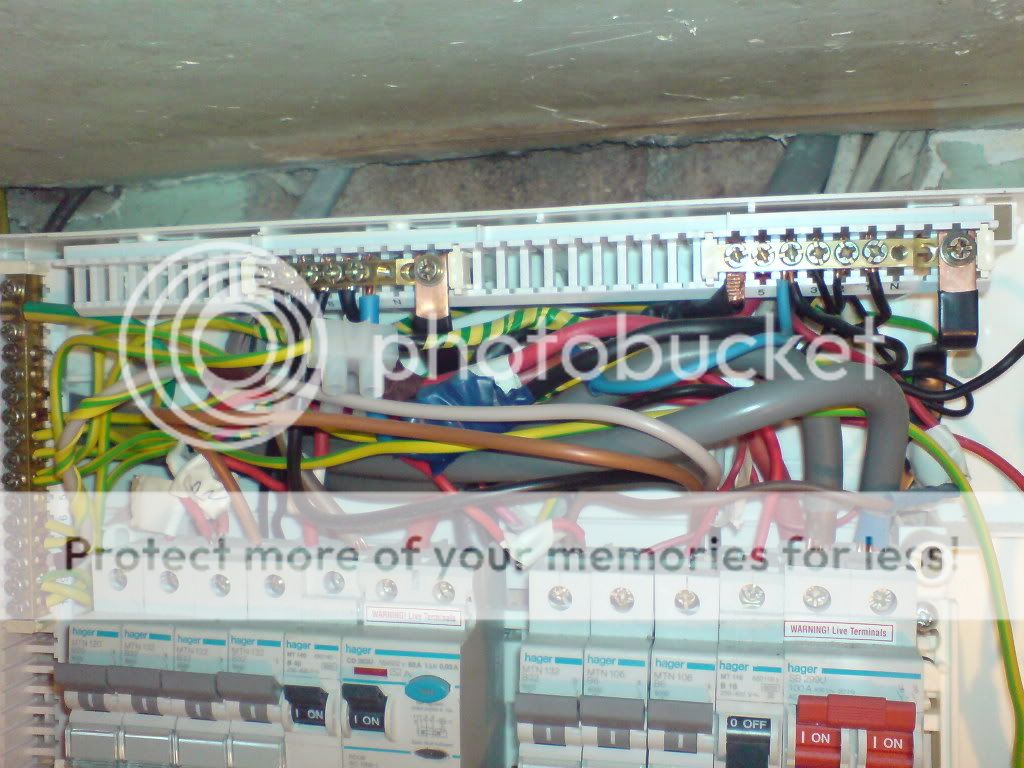

I attended the property this afternoon and carried-out a Visual Condition Report. I've uploaded the redacted document for your perusal. I also carried-out a Ze test (fine), RCD trip times (fine) and Zs tests on all the sockets (not fine). I also did end-to-end tests on two RFCs. The house ring was fine, but there is an issue with the kitchen ring. Someone (Kevin the kitchen-fitter, no doubt) has made alterations which have resulted in a complete loss of continuity of both CPCs at one of the kitchen sockets. Zero volts between live and both CPCs. So, whoever did the board changeovers either knew about this fault and simply ignored it, or, as is much more probable, didn't do any testing prior to installing the new boards. All the issues that I found are detailed in the VCR. I look forward to reading your comments!

Now for the moment that you've all been waiting for ...... the photos:

View attachment 45196

View attachment 45197

View attachment 45198

View attachment 45199

View attachment 45200

View attachment 45201

The customer informed me that it was a wetpants who did all of this. I've yet to decide a definite plan of action to rectify this lash-up, but I'm inclined towards ripping the lot out and starting again from scratch using a Hager unit instead as I absolutely hate BG boards. I think that the Axiom 3-way garage unit that is being used to supply three off-peak storage heaters should be replaced by a better-quality unit with 100 amp main switch and RCBOs. I propose to relocate this board further to the left so that I can utilise the adaptable box that is being obscured. I could then take all those bad joints inside the box and crimp them or use Wagos. Your thoughts please guys and gals.

As we all had already anticipated, the customer did not receive an EIC.

Nice work! Hope the customer is satisfied.

Although comment would be you're only supposed to code non compliances that affect the safety of the installation, so lack of labelling could only be an observation could it?. Also no CPC continuity would not need further investigation in order to classify it, although investigation would be needed to repair. Should just be coded straight away.

As I said, I figured I'd tag a few of you in but could only remember JK and couldn't search on location, so sorry about that.

I'm always open to working with other local electricians whenever the need may arise.

I'm always open to working with other local electricians whenever the need may arise.