I'm refurbishing my own workshops and fitting a new central three phase compressor and three phase dust extractor.

Both these appliances will be controlled by remote START/STOP switches, next to multiple compressed air and vacuum points, which may be in different buildings.

For future-proofing I want to have more than one control station for each appliance, for convenience when moving machines around the workshops.

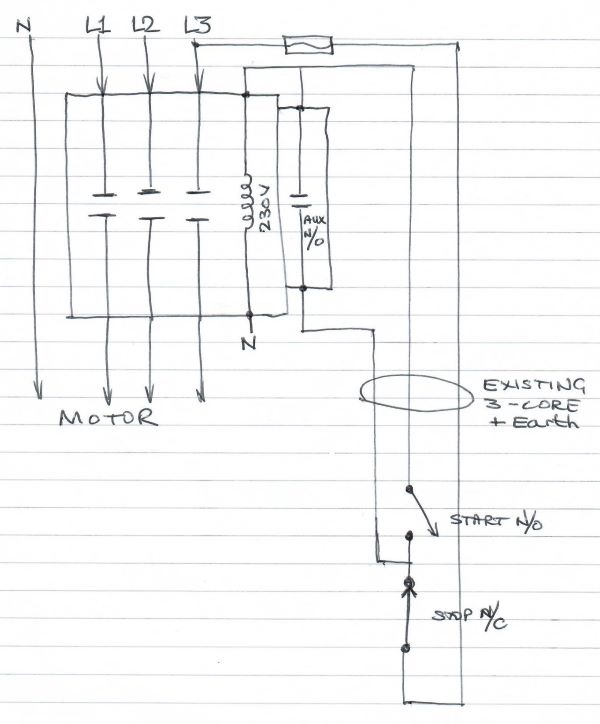

Using what I believe is standard wiring for a three pole + aux n/o contactor (sketch below) it’s easy enough to use the existing three core and earth cabling for one station only, latching the contactor.

But to allow additional remote stations I can’t think of a way to do it without using four core + earth. An unlimited number of n/o START switches can be installed in parallel, but the STOP switches need to be in series as they are n/c.

Of course simple on/off switches powering the contactor would work, but that would be a terrible idea as you’d have always to switch off from the same position as you switched on.

Is there some clever way of making the wiring easier and clearer than having a long loop for the stop circuit? This would be particularly confusing if the geometry of the cabling is not simply point-to-point but partly a 'star' configuration.

I’ve not done this before and have no idea if there’s some standard method I’ve missed.

Thanks, Mark

Both these appliances will be controlled by remote START/STOP switches, next to multiple compressed air and vacuum points, which may be in different buildings.

For future-proofing I want to have more than one control station for each appliance, for convenience when moving machines around the workshops.

Using what I believe is standard wiring for a three pole + aux n/o contactor (sketch below) it’s easy enough to use the existing three core and earth cabling for one station only, latching the contactor.

But to allow additional remote stations I can’t think of a way to do it without using four core + earth. An unlimited number of n/o START switches can be installed in parallel, but the STOP switches need to be in series as they are n/c.

Of course simple on/off switches powering the contactor would work, but that would be a terrible idea as you’d have always to switch off from the same position as you switched on.

Is there some clever way of making the wiring easier and clearer than having a long loop for the stop circuit? This would be particularly confusing if the geometry of the cabling is not simply point-to-point but partly a 'star' configuration.

I’ve not done this before and have no idea if there’s some standard method I’ve missed.

Thanks, Mark