T

theroadblock

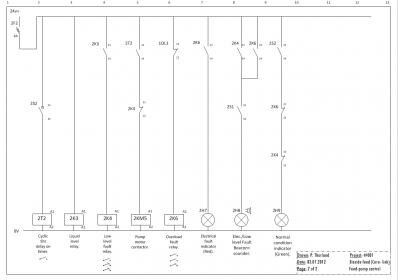

Not sure if the image will come through properly so its ledgible but here goes, my first attempt at designing my own control circuit, its basically just controls a pump that is going to be feeding biocide into a tank once every 5 hrs, bearing in mind this is just the control side of it and there are still a few modifications to be made, first thoughts? constructive criticism welcome :smiley2:.

Uploaded with ImageShack.us

Uploaded with ImageShack.us

Attachments

Last edited by a moderator:

. '2S2' is going to be a keyswitch for maintenence personnel, (i know it needs a better suited symbol) lol, when switched off will turn the beacon /sounder off but leave a red Indicator on the front of the panel on for the purpose of not ****ing people off haha,

. '2S2' is going to be a keyswitch for maintenence personnel, (i know it needs a better suited symbol) lol, when switched off will turn the beacon /sounder off but leave a red Indicator on the front of the panel on for the purpose of not ****ing people off haha,  .

.